Taking advantage of the first non-rainy weekend day in ages I decided it was time to get the engine back in the van.

First job was to get the old clutch operating arm out, and the new one in. So, first remove the lever that is a ‘slide fit’ onto eth operating arm: - here is an exceptionally dark picture!

Tried a puller, tried brute force, tried heat, tried the puller again, tried even bigger brute force, but it was not coming off. It appeared the end was slightly mushroomed (before the brute force I must add), so out with the hacksaw, popped it in a vice and got the big hammer out, but driving from the cut side:

New operating arm from a reputable supplier didn’t fit – the shaft was too big to fit in the hole in the gearbox housing, Taking a flat file to it showed that the end was effectively concave, as the file didn’t touch the middle. Went through a careful ‘file and trial’ process until it fitted and operated smoothly. Here’s a pic of the finished filed profile – note the very high quality weld too!

I hate it when new parts are poorly made / finished, especially when you order from one of the supposedly better suppliers!

Next to tidy up the engine bay – here it is mid clean, just sorting out the wiring to get rid of the variuos bodges, and to remove the single carb manifold heater, cut off solenoid etc etc.

Next step is to drag the engine out of the garage and slide it in.

Main hassle, lift it high enough off the ground to get the jack under, when you are by yourself and you don’t have an engine crane. My (probably dangerous and foolish) method is to take a piece of nylon rope, a big bit of wood and a steel bar. Make a loop in the rope, sling it over the wood and twist the steel bar in the middle of the loop. As you twiddle the rope tightens, shortens and lifts it off the ground... Just make sure the rope is thick enough and can take the weight. A piece of wire fed through the hole in the steel bar means you can tie the bar up and hence retain tension. DO NOT GO UNDER THE ENGINE WHEN IT IS HELD LIKE THIS!!

Jack under and going up (I still keep tension on the top rope at this point just in case it falls off:

In and bolted up (dark picture it was getting dark by this point):

Note that as you slide it back in it can ‘stick’ as the clutch plate tries to slide onto the splines of the gearbox shaft – a quick turn of the engine can help it slide on more easily...

Process halted for the day whilst I had to turn my had to some light panel works on my neighbours Corsa where one of my roof tiles blew off and went straight through the bonnet... Bother.

Sunday I had a look at the interim engine I had put in, bought off a 80-90 member. 10 points for anyone who can tell me what’s wrong with this DG head –

That’s right, it’s got round DF inlet holes in (wouldn’t have known the difference before I started this project!). So I have two DF heads, but late style bearings and the second oil pressure switch by the filter. It also has low oil pressure when hot, and when you turn it over the crank goes in and out, in and out, so the end float varies depending on crank position! Not the best investment I ever made. Any takers for a door stop / paperweight!? Anyone buy scrap engines?

Quick question, does anyone know what size threads the manifold heater thermo switch is (doesn’t match any of my assorted bolts – fine pitch?) as I don’t need it and would like to blank it off.

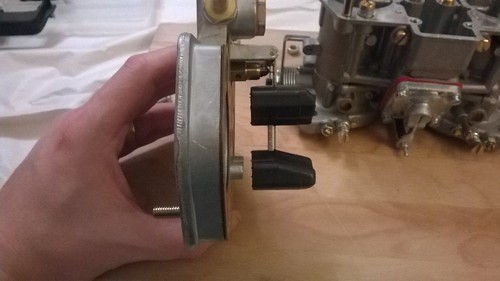

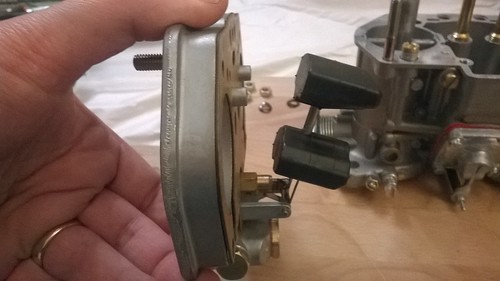

So left to do – finish the wiring, paint and replace engine tin, connect up the hoses, pop on back box, set static timing and set up Dellortos (order going in Friday (payday!))

Thoughts have turned to running in. Two schools of thought on t’internet:

1) Drive it like a nun, let everything bed in gently

2) Drive it harder to develop cylinder pressure and bed rings

Both make sense when you read them, what do people do? Is prolonged idling an issue as need to get it MOT’d as soon as its running, which will be at least ½ an hour on the ramps at idle!

If you made it to here, congratulations on your stamina....

Cheers,

Alex