Page 11 of 17

Re: The SA 2.6i Microbus thread

Posted: 15 May 2014, 15:28

by silverbullet

Had a bit of an ear-bashing from Hutch re: BLOS (he thinks any kind of carb are witchcraft) and I have now seen the light brothers! Inlet manifold is coming off tonight for some precision drilling and tapping

The air filter work hasn't been wasted, it's now servicable with UK parts. So if anyone is interested, there's now a BLOS that's been tapped for idle air and engine breather c/w elbows and a zero hours R90e vapouriser, up for grabs..?

Re: The SA 2.6i Microbus thread

Posted: 15 May 2014, 16:03

by Wychall

So are you going for lpg injection? What will you be driving it with?

I'm still looking for someone that can give me the definitive on Megasquirt for lpg.

Re: The SA 2.6i Microbus thread

Posted: 15 May 2014, 18:19

by silverbullet

For now, AC Stag 6 (300) will do as its simple and reliable according to Da Man who will do the laptop bit...

PS getting the inlet manifold is proving to be a struggle. Just chipped the end off a hex driver in the rearmost bolt

Re: The SA 2.6i Microbus thread

Posted: 16 May 2014, 19:45

by silverbullet

Manifold off. Went well this time, sunshine always helps!

The offending fractured bit end, that fell out as I was whacking the Irwin to make it release. Typical!

Re: The SA 2.6i Microbus thread

Posted: 18 May 2014, 13:08

by silverbullet

Whats wrong with this picture? (clue: soot on #3 inlet branch)

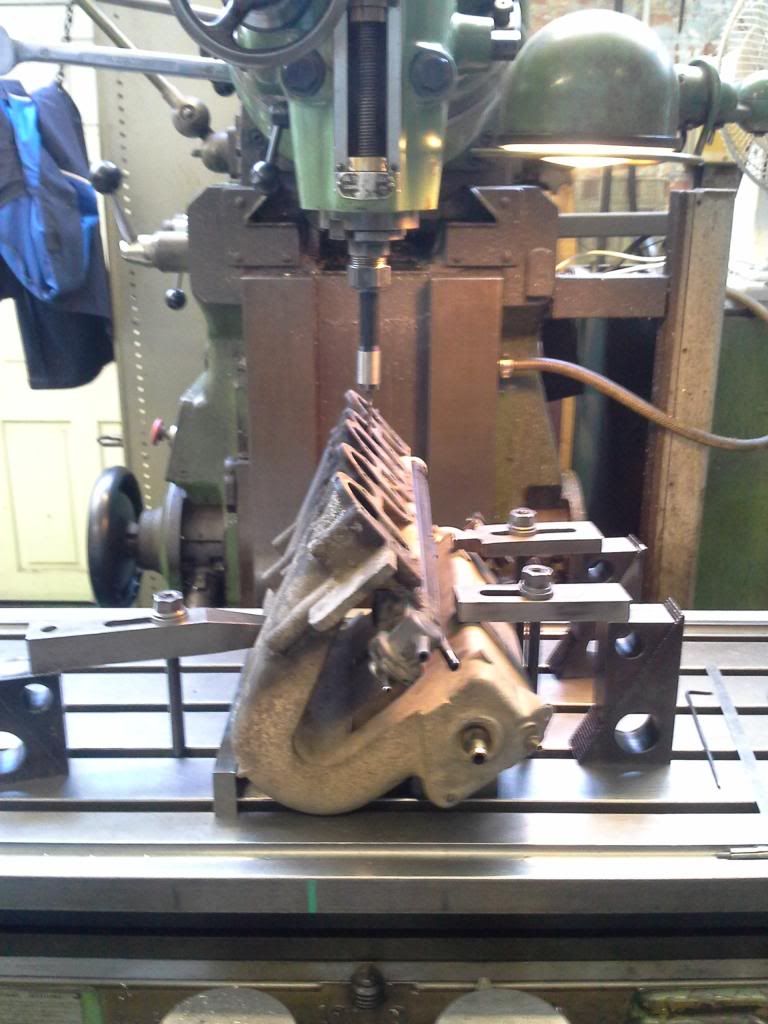

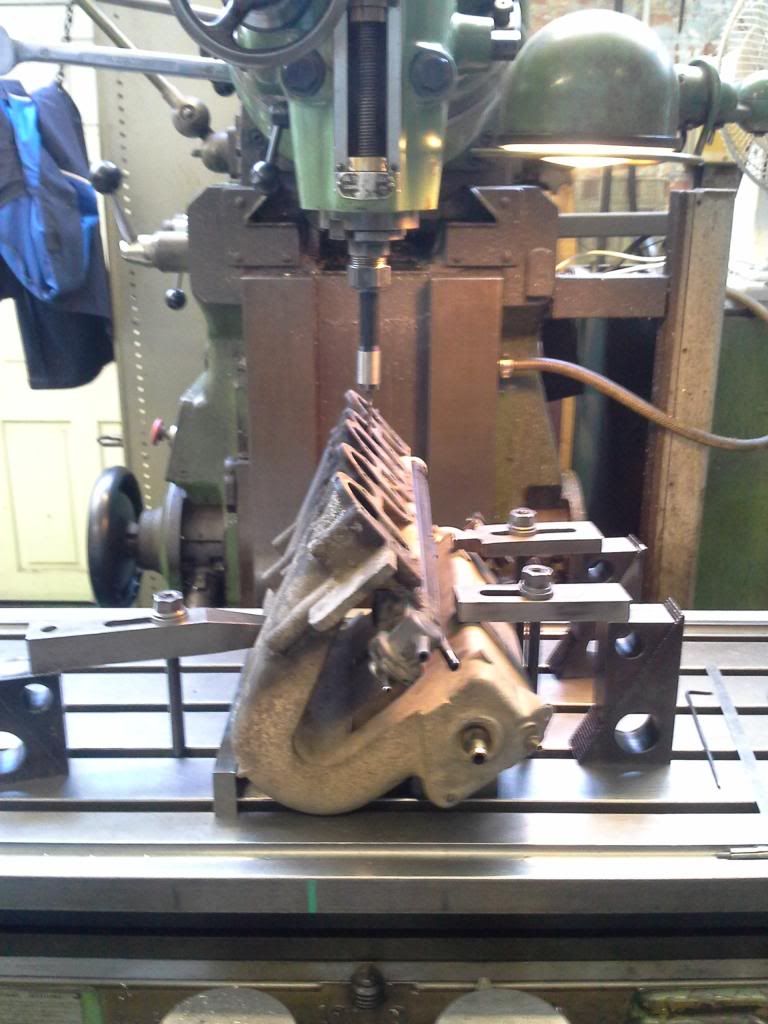

Inlet manifold now drilled and tapped M6x1 for lpg nozzles. This is the only way to do the SA 2.6 manifold but since it is identical to the T4 2.5i part, this should interest anyone who is putting up with an induction ring system on a petrol T4:

The whole job took less than 3 hours, half of which was getting the set-up and getting the manifold square on the machine. Tappings are nice and close to the petrol injectors. Good job too as its the only place they will fit:

Here is where the tapping breaks out and where the nozzles will go in. T4's might have a bit.more room as they are sequential not batch-fire inj as per this early 2.6i

Re: The SA 2.6i Microbus thread

Posted: 24 May 2014, 11:46

by silverbullet

Sheared bolts now out of engine bay rear panel, one went straight down the middle, one less so... helicoil time.

A lot of effort and nothing to show, SA owners get comfy first as the hatch edge does dig into your chest when drilling.

The bolts are well over-length too so rust up a treat. Expect the same on yours.

Re: The SA 2.6i Microbus thread

Posted: 25 May 2014, 14:56

by silverbullet

Engine is now back up, so I thought that I would spin the crank damper 180 and have ignition timing marks that mean something (previous mechanic cockup, but I didnt notice) but true to form, I made such a good job of torquing & locking the bolt after replacing the cambelt ( when I didnt notice the pulley), I can't get it undone! Managed to distress my crank locking tool as well, so that will need re-making sometime...

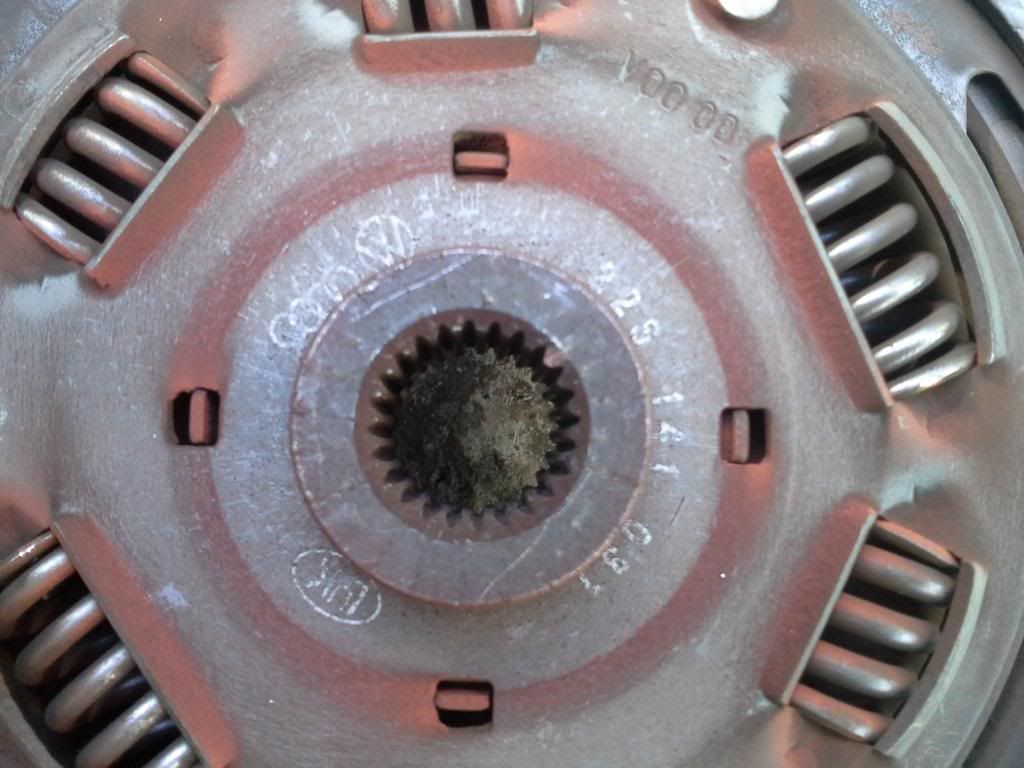

So I took the clutch off. Well here's a thing:

Maybe this is the original clutch after all?

Re: The SA 2.6i Microbus thread

Posted: 25 May 2014, 16:44

by silverbullet

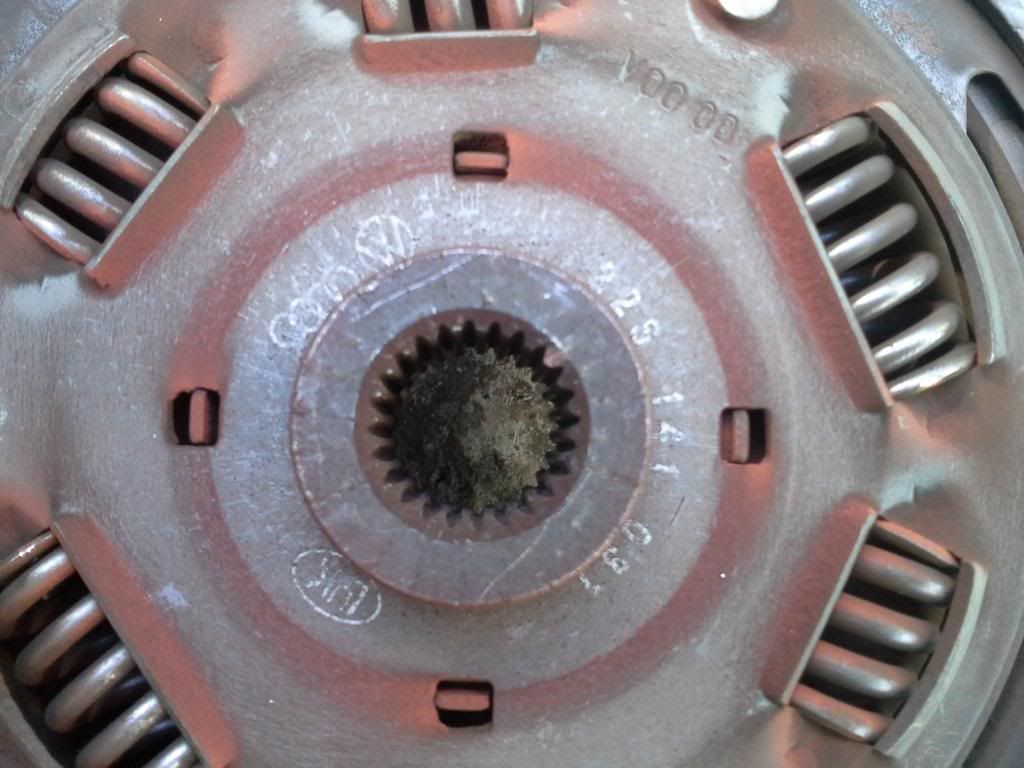

And the flywheel has trigger pins just like a 20v with sequential injection, but this earlier engine doesn't use them:

Anyone good at identifying fuel pumps? Never noticed before but it has a rigid plastic HP hose held on with a nut/olive plus a mini timer plug. Not like a regular T3 pump so maybe Audi 90 again?

Re: The SA 2.6i Microbus thread

Posted: 24 Jun 2014, 09:32

by silverbullet

Squeaky bum time!

Lpg wiring loom just about in but no manifolds fitted because I am waiting on exhaust bits from USA; new clutch worries here

http://forum.club8090.co.uk/viewtopic.p ... 5#p8001305" onclick="window.open(this.href);return false; and I haven't had the rack for the Dehler/rooftent combo welded yet or prepped the grp yet

Re: The SA 2.6i Microbus thread

Posted: 29 Jun 2014, 21:06

by silverbullet

I finally sorted the iffy heater control valve cable! The better part of a day's fannying about but the controls now have a very light action. Why VWSA never took this approach in the first place I can't imagine...

The problem. SA has a special cable to connect to the Audi 80 control panel and it is far too short imho, so has a tortuous path down to the valve which ended up with it getting kinked:

I had a new rhd one, but it needed the outer shortening to achieve the correct end-to-eye dimension as the original. This meant cutting the end off the SA outer and hooking out the inner with a small drill:

Then the outer could be trimmed back (35mm in the end, but an inch more wouldn't matter as you will see later)

Then the locating tag could be refitted to the rhd cable and a new eye formed (not easy!)

The new cable was a fiddle to refit but the control panel will roll over just enough to give access. Take out the dash pod, radio and heater ducting for access. You'll need it!

The cable still had a poor approach angle to the valve , so I drilled a new hole at the "corner" of the tunnel where it would still be hidden by the heater ducting:

From underneath:

The cable now runs under the radio, past the vaccum actuator and in a large arc down to the grommet and in a straight line to the valve. It is hardly visible from the passenger seat, hence the comment that it could be an inch shorter without any worries.

All well worth the effort and eliminates another 22S part.

PS remove the top 450mm of the rubber star-section anti-rattle sheathing from the cable, the reduced bulk helps it settle back under the radio and achieve a more gentle line.

Finally I swapped the awful T3 "beeper" for some mk3 golf horns. Much more German-sounding!

Re: The SA 2.6i Microbus thread

Posted: 09 Jul 2014, 20:28

by HarryMann

Blimey...

Read the lot... exhausted!

Re: The SA 2.6i Microbus thread

Posted: 09 Jul 2014, 21:19

by silverbullet

So is working on it Clive!

There was a slight whoopsie with the clutch plate, should be back (again) tomorrow.

Can't fault Auto Industrial Friction Serv, they had it collected and give first class service at very reasonable costs indeed.

Recommended.

Re: The SA 2.6i Microbus thread

Posted: 11 Jul 2014, 20:06

by silverbullet

Hurrrah and huzzah! Clutch came back and all is well. Fitted it before the light started to go, trans back in tomorrow

Then I can get the lpg wiring finished off, get it running again and then harass my tame welder about the alloy frame for the Dehler...

Re: The SA 2.6i Microbus thread

Posted: 12 Jul 2014, 20:57

by silverbullet

Had two goes at fitting the transmission today. First attempt showed up less than exemplary clutch alignment, despite using my proper Sykes Pickavant tool. Got to within 10mm and would NOT go on. So out it came again, paid more attention to getting the "slack" on the tool symmetrical, both vertical and horizontal.

Trans went straight on

Wasted a lot of time refitting the trans nose mounting, fitting lpg tails on the manifold spuds, breaking wires on the idle valve plug...

Electrical day tomorrow, after CV joints and gear linkage. Rover SD1 air filter can needs a bit of a tweak too.

Nearly up and running again.

Re: The SA 2.6i Microbus thread

Posted: 12 Jul 2014, 21:03

by silverbullet

Bonus was that the trans was a doddle to refill, but I could only get 3.5l in, despite the van being nose up.

[img]

http://img.tapatalk.com/d/14/07/13/yry4atyr.jpg[/img]

Must be that LSD being slow to fill up...