Page 1 of 24

Rebuild Thread (Probably)

Posted: 13 Oct 2018, 17:48

by Ciaraneng

So I've had some

problems with white smoke on start-up and poor compression on my 1983 1.9 DG. I decided to drop out the engine using itchyfeet's

winch method and I followed MartinR's

removal instructions and the Haynes manual. Some photos are

here.

My plan is to replace all seals and piston rings and to sort the rather excessive end float. I will take a look at the oil pump and see if I can take the pressure up a bit from the 30psi at 2000 rpm.

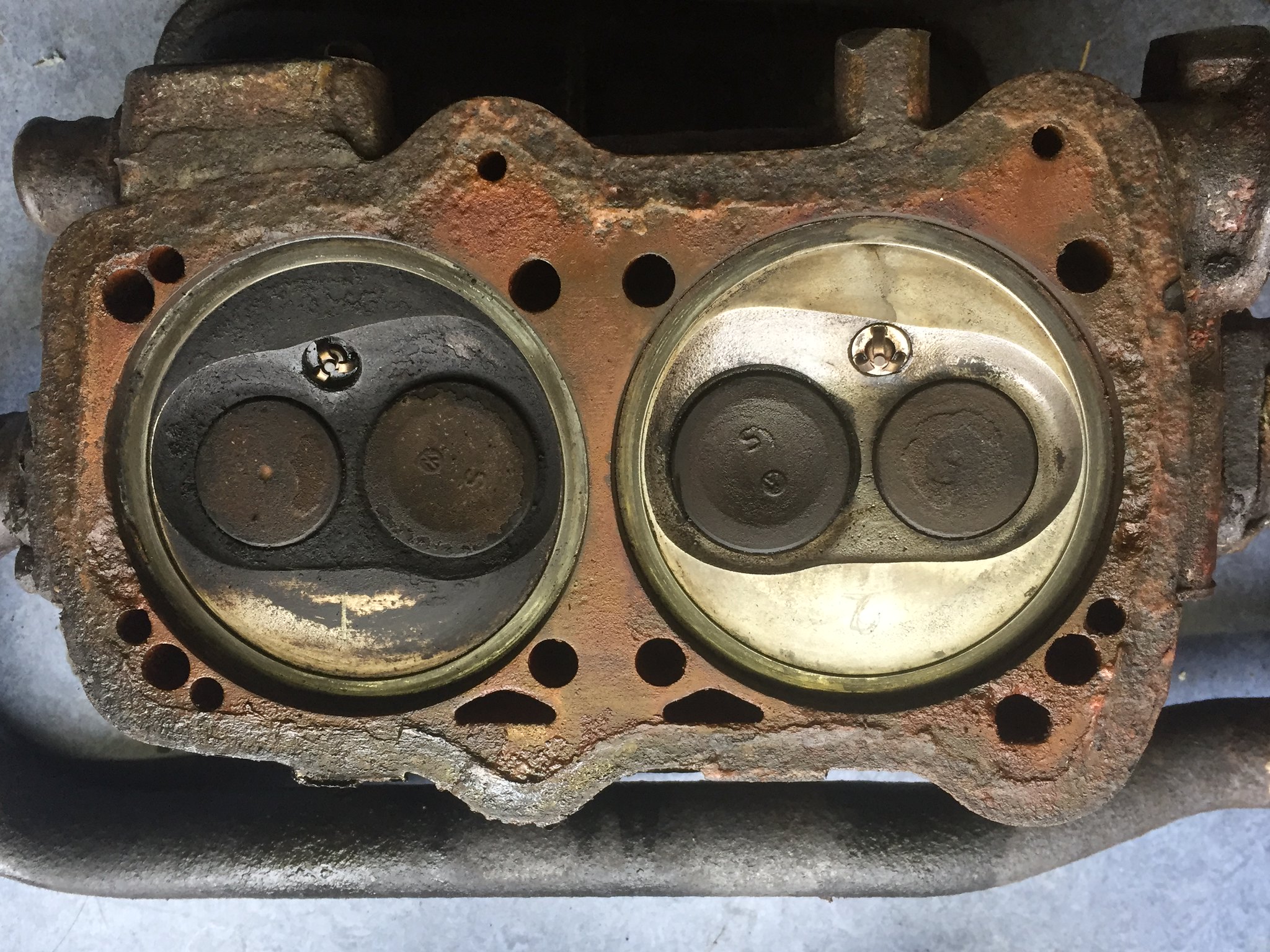

I have a lot of corrosion on the heads and some on the case. Also a lot of pitting on the heads. Can someone here take a look at the photos and help me understand the condition of my engine? I'd like to understand what needs repair/replacement and what are the main things I should work on first. Any guidance would be much appreciated.

Thanks in advance.

Re: Rebuild Thread (Probably)

Posted: 14 Oct 2018, 21:25

by 123-jn

I would start by cleaning off the seal mating surfaces on the base of the heads just so you can see the real depth of the problem. Sometimes you can fill the pits with liquid metal and smooth off but looking at your photos some of the pitting goes over the edge of the combustion chambers where the green cylinder seals mate. If this has gone too far the heads will be scrap I'm afraid. B' works had polish cast heads for about £180 each or the improved version made by AMC for about £312

Re: Rebuild Thread (Probably)

Posted: 14 Oct 2018, 21:36

by 123-jn

From my experience The pistons are probably ok with a clean and measure to check, fit new rings. The barrels are probably ok but you haven't shown any pics of the seal groove around the edges. If the grooves are good then a hone will probably suffice (check by measuring first to ensure they are not too oval.) The head studs look ok but the case needs a good clean up and oil ways a good clean through. Check all the core plugs are not leaking especially the one next to the head stud inside the case water gallery (it plugs the main oil gallery). Get the crank measured . I have not yet found one that needed anything other than a polish and new bearings (4 engines rebuilt), but sometimes the big ends need a small .25 re size. New mains and big ends, make sure the rod ends are not Oval. The small ends are often OK but check there is only a very small amount of play. New rings seals and heads you should be good. You may find that your valves having been cleaned up are perfectly ok to be used again in the new head with a regrind. I usually manage to re use most of them. Slam it all back together very carefully!!! Curil T on the case halves or Blue hylomar and the black gunge that comes with the gaskets on the water jacket seals. A bead inside the lip of the seal and another around the head mating surface. Yellow gunge out of the gasket set under all the nuts/washers. I always use stainless studs for the exhaust with deep brass nuts for eas of undoing again and stainless bolts and brass nuts on the rest of the exhaust.

Re: Rebuild Thread (Probably)

Posted: 16 Oct 2018, 20:18

by Ciaraneng

Thanks for the advice 123. I have cleaned up the heads a bit and the barrels and it looks as if I will get away with the pits as they don't extend down as far as the o-ring groove. They are only about 1.3mm deep so I'm hoping they can be filled with liquid metal. Can you recommend a liquid metal brand?

Sorry, what/where are core plugs? I was not planning to open the crank case as my oil pressure is not too low. Would you advise to go in now that I've gone this far? This is my first ever rebuild attempt so I'm afraid if I go much further I'll mess something up that I can't correct.

Also, I was planning to leave the exhaust attached as it's not currently leaking and I suspect all studs will break. If it ain't broke and all that. Is it necessary to remove the exhaust? Maybe I'm missing something. Thanks again.

Re: Rebuild Thread (Probably)

Posted: 16 Oct 2018, 21:08

by 937carrera

I'm going through a similar process on my "Unknown" engine and posted something in the past few days . Just a small amount of metal missing on one of my heads, right near the water gasket. I'm planning on using JB Weld (standard, not quick) on mine.

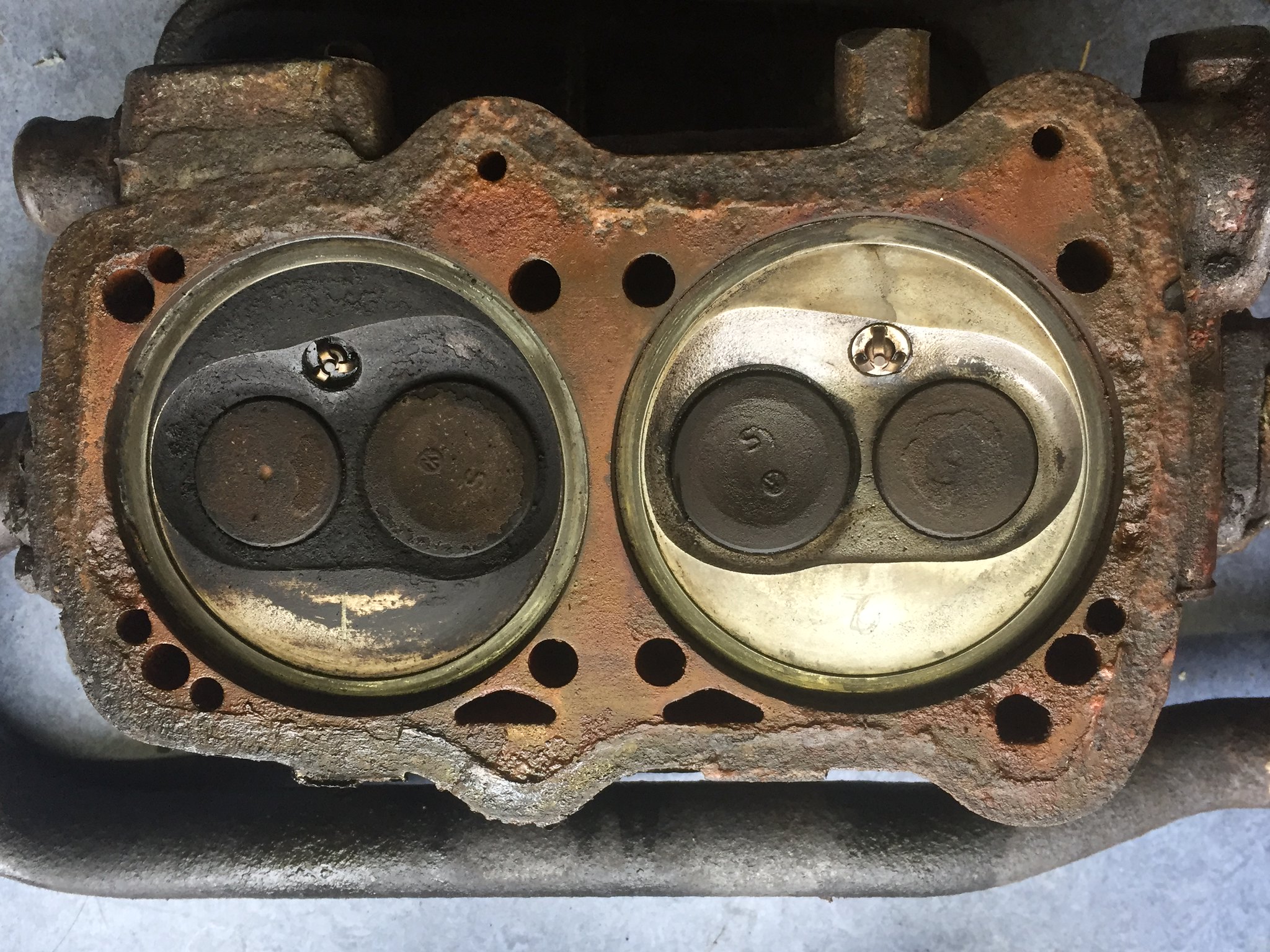

On the original photos number 2 looks much cleaner, is that what it looked like when you took the head off ?

It's up to you whether to split the case or not. If I didn't know the history of the engine I would, but if you aren't concerned, just do the top end.

Do you have the kit to measure pistons and bores - let's have a look at those too.

Re: Rebuild Thread (Probably)

Posted: 16 Oct 2018, 21:43

by Ciaraneng

Thanks carrera. I might order some JB Weld. Now you mention it, the head on cylinder No. 2 cleaned up straight away with a rag. Just an oily residue but no built up Carbon. I wonder was it steam cleaned and was that where the white smoke was coming from? I don't have micrometers to measure the pistons and the bores unfortunately. I might check at work. Is it worthwhile dropping them into an auto engineering shop?

Re: Rebuild Thread (Probably)

Posted: 16 Oct 2018, 21:50

by 937carrera

Ciaraneng wrote: I wonder was it steam cleaned and was that where the white smoke was coming from?

That's what I was thinking - the steam coming from the coolant leak. You need to check that cylinder more closely, unless you already know where the leak was. Steam can be very good abrasive for metal.

Spend around £40 on a bore gauge and 75-100mm mic and you can do the checks yourself, but you don't have the engineers experience.

Re: Rebuild Thread (Probably)

Posted: 16 Oct 2018, 22:14

by Ciaraneng

Thanks Carrera. Great spot. I'll take a closer look at that cylinder, head and seals see if I can see wear. I'm a mech eng and have done bore and cylinder measurements in non-auto applications before so I'll see if I can locate or buy a set of 75-100mm micrometers. Can cheap eBay mics be trusted for the tolerances in question? I have paid hundreds in work for this type of gear before.

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 07:08

by 937carrera

Ciaraneng wrote:Can cheap eBay mics be trusted for the tolerances in question? .

It's what I and others are using. I am sure they are not as accurate as the likes of Mitutoyo etc, and probably a little more difficult to use to get consistent measurements, but good enough for 0.01mm accuracy, as opposed to the higher quality ones which are good to 0.001mm.

I was having a suspension component repaired after breaking once. The engineer commented that there was originally about 4 thou clearance, but he had fettled it to make it better.

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 12:09

by itchyfeet

Ciaraneng wrote: I'll see if I can locate or buy a set of 75-100mm micrometers. .

you need 0-100 for an engine rebuild

I bought Moore and Wright 215, the way I see it is you can always sell them on if you think they will never be used again, realy cheap stuff is worth nothing second hand

https://www.ebay.co.uk/itm/Moore-and-Wr ... :rk:4:pf:0" onclick="window.open(this.href);return false;

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 17:57

by Ciaraneng

Thanks Paul. I should be able to get hands on a good set of micrometers no problem.

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 18:40

by Ciaraneng

937carrera wrote: You need to check that cylinder more closely, unless you already know where the leak was.

I had a closer look and think I have found the source of the problem. It looks as if someone has replaced the seals previously and used a screwdriver to remove the old seals. In doing so they gouged the seal area of head. It feels quite deep to the finger nail.

I've been trying to convince myself I don't need to buy new heads but with this latest 'find' I'm less and less sure I can get away without spending a wad of cash.

Are there any thoughts on the merits of spending the extra £260 on the more expensive heads? I'm leaning towards the less expensive heads as we already have 2 other cars in the drive so this van will be seeing no more than a few thousand miles a year.

On a separate question,

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 18:44

by Ciaraneng

On a separate question, am I correct in assuming that the coolant pump should move fairly freely. My one is very stiff and hard to turn. I'm guessing that's another one for the shopping basket?

The good news is that they are only £38...

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 18:50

by 937carrera

Ciaraneng wrote:

I've been trying to convince myself I don't need to buy new heads but with this latest 'find' I'm less and less sure I can get away without spending a wad of cash.

Unless it's how you have cleaned the head, interesting that you can see a difference in colour of the head either side of a line from the gouge.

I would have though you could get that tigged up and machined to the correct dimension. A lot cheaper than a pair of heads.

New water pump required then

Re: Rebuild Thread (Probably)

Posted: 17 Oct 2018, 19:12

by 937carrera

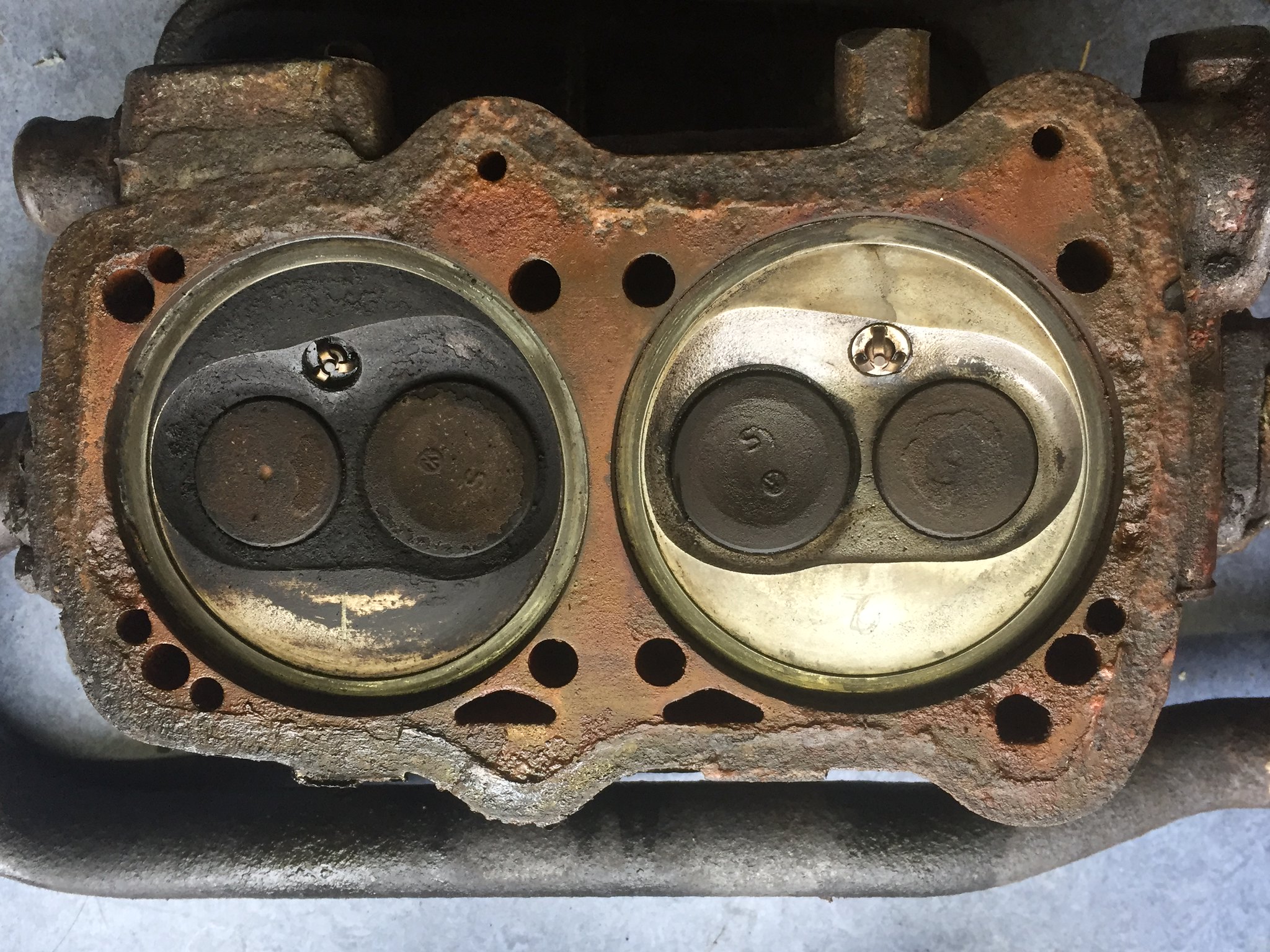

Another question, cylinder 1. I spotted this in picture 3,but it is visible just before 9 'o clock on picture 1.

Is that rust on the top of the compression ring, or a hole in the ring ?