Page 1 of 1

Snapped Cylinder Head Stud - HELP!

Posted: 18 Apr 2018, 20:37

by stretch616

I've been fitting some gaskets in out if the water pump up to the cylinder head. When I came to tighten the bolts on the cylinder head side, one of the pressed studs has snapped off. Does anybody have any idea on where to go from here, I've had a bit of advice from a friend and it's not such a simple job so I'm looking for anyone advice on this please.

Re: Snapped Cylinder Head Stud - HELP!

Posted: 18 Apr 2018, 20:54

by kevtherev

How much stud is left showing?

Re: Snapped Cylinder Head Stud - HELP!

Posted: 18 Apr 2018, 22:18

by stretch616

Just the width of the flat part on the end of the pipe section. I'm guessing about 5mm or so

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 06:35

by itchyfeet

stretch616 wrote:I've been fitting some gaskets in out if the water pump up to the cylinder head. When I came to tighten the bolts on the cylinder head side, one of the pressed studs has snapped off.

Can you be a bit more specific, like what engine, and what stud, I can't figure it out.

Even better is to get a photo up.

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 07:37

by stretch616

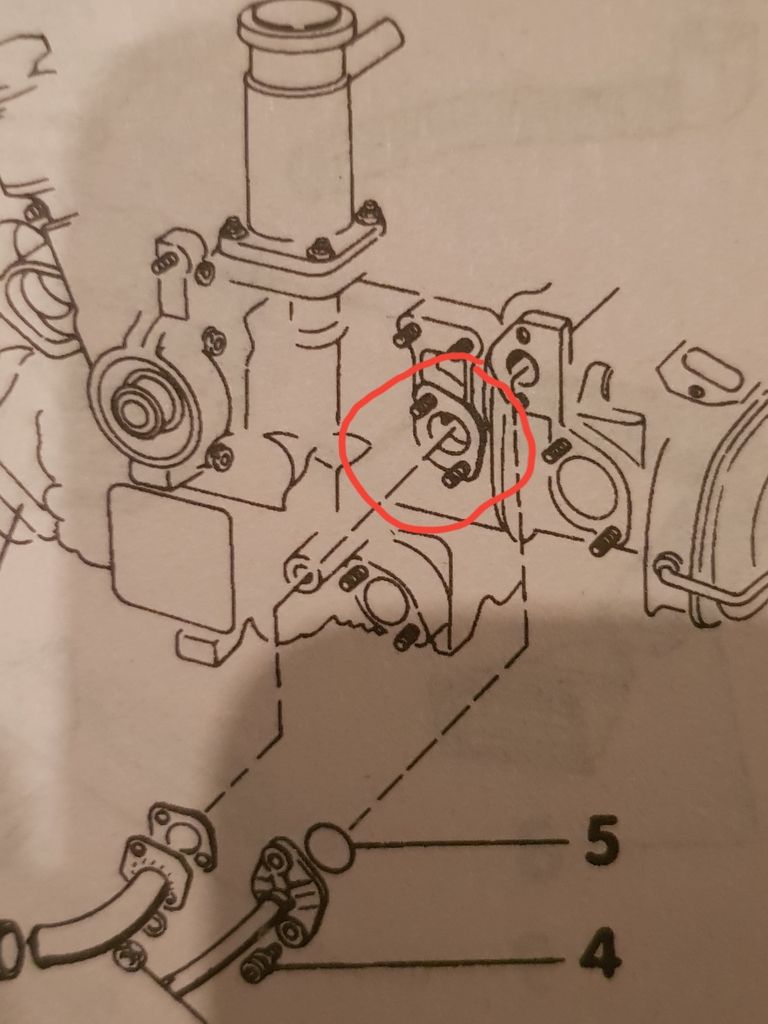

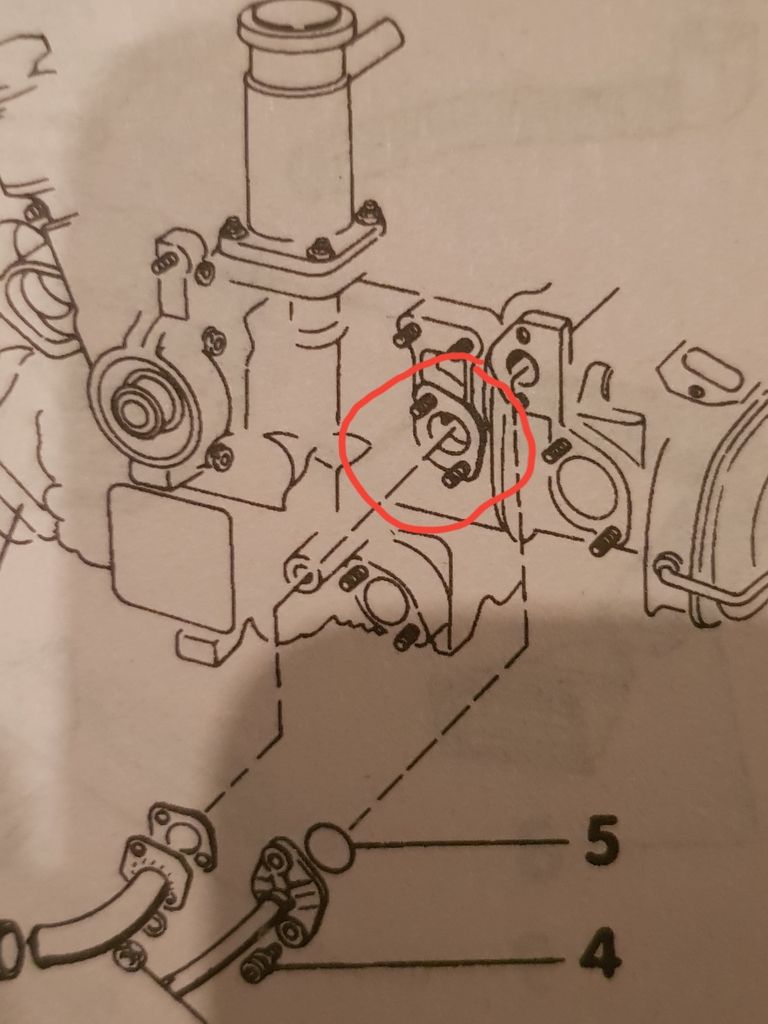

Sorry, totally forgot to put in the engine type.

It's a 1.9 DG and here's a picture of the problem and I've highlighted the Part and the bit in the Haynes manual

[img

[/img]

[img

[/img]

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 09:30

by Ian Hulley

The easiest way is to weld a nut onto the remains of the stud and then while the stud is hot wind it out ... if you can't do that then it's a flatten the surface, centre-pop it and carefully drill the centre out and use an easy-out (like a left-handed drill) in conjuction with either heat or Freeze-it spray to wind out the stud. All of this is easiest done with the engine out of course

.

Be VERY aware of the risk of fire ... petrol pipes, carb etc etc ... we don't want to have a flying visit from Captain "cock"-up now do we.

Ian

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 11:50

by itchyfeet

Agree with the nut welded on but personally I would not go near an easy out, if the stud shears off flush then drill it out and helicoil it, just don't drill too deep!

easy outs are hardened, when the easy outit snaps off ( they always do) you can't drill it out you will have to remove the engine and have it spark eroded.

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 14:20

by Ian Hulley

itchyfeet wrote: easy outs are hardened, when the easy outit snaps off ( they always do) you can't drill it out you will have to remove the engine and have it spark eroded.

Ey up Paul, I've had good results with them in conjuction with heat/Freeze-it ... you need 'the feel' for when they are flexing.

Ian

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 15:51

by 937carrera

I recently had to remove some exhaust headers from a head. Every single one of them snapped off. Completely par for the course for this particular job from specialists I know. The studs seem to be made of hard cheese.

In my case I simply drilled down into the stud and opened the hole out with progressivelly larger drill bits. In 6 out of the 8 cases I was able to drill out and then clean the threads up with a tap. Two of them needed helicoiling. All of this was by hand, no bench drill arrangement, steel studs, aluminium heads.

The question is, do you have sufficient access to get a drill in and keep it straight, if welding a nut on does not work ?

I haven't had much success with easy outs. In almost every case I have had the "feel" and stopped trying before the easy out broke

You'll probably find that the best approach is to find someone with an oxy-acetylene torch. Penetrating fluid followed by 5 minutes heat and it'll probably come out with mole grips.

Re: Snapped Cylinder Head Stud - HELP!

Posted: 19 Apr 2018, 16:01

by itchyfeet

Ian Hulley wrote:itchyfeet wrote: easy outs are hardened, when the easy outit snaps off ( they always do) you can't drill it out you will have to remove the engine and have it spark eroded.

Ey up Paul, I've had good results with them in conjuction with heat/Freeze-it ... you need 'the feel' for when they are flexing.

Ian

yeh maybe they are good with experience but would you recommend then to a novice?