Page 21 of 30

Re: WBXlog

Posted: 31 Mar 2017, 16:39

by itchyfeet

500 mile oil and filter today, no bits in the oil, treated it to a rev limiting rotor arm ( please don't tell me they are unreliable), dizzy cap and plugs.

I had forgotten how black oil gets running on petrol, my lpg van isn't this bad after thousands of miles.

Checked compressions and same as before 13 to 14 bar

must get push rod covers on

Re: WBXlog

Posted: 31 Mar 2017, 20:40

by ajsimmo

itchyfeet wrote:treated it to a rev limiting rotor arm ( please don't tell me they are unreliable)

Ok, you can rely on them to fail.

Re: WBXlog

Posted: 31 Mar 2017, 20:50

by itchyfeet

Everything fails eventually.

Re: WBXlog

Posted: 14 May 2017, 15:29

by itchyfeet

Just turned the first 1000 miles today

Re: WBXlog

Posted: 13 Jul 2017, 21:14

by itchyfeet

2000 miles not much to say other than the extra power of a DJ over a DG is well worth the effort

Re: WBXlog

Posted: 23 Aug 2017, 20:19

by Bigjcc55

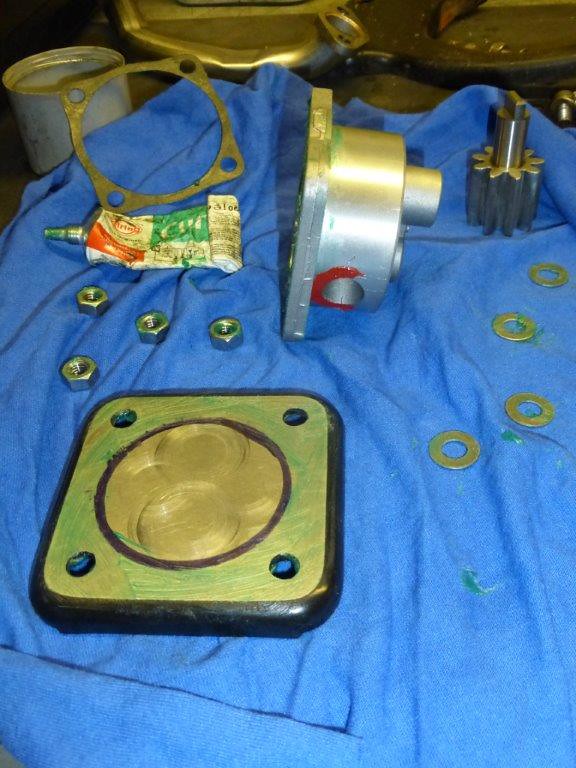

If don't mind me asking where did you get the tip to add the o ring on the back of the oil pump?

Sent from my iPhone using Tapatalk Pro

Re: WBXlog

Posted: 23 Aug 2017, 20:34

by itchyfeet

Marco Mansi.

he fits three o rings and uses no gaskets but the one shown is the easiest and IMO the other two gaskets works well enough if you reduce the endfloat to zero by wet and dry on the pump body and use the gasket to provide the endfloat.

If ouu never heard of Marco he has been building turbo race WBX for many years and knows his onions

Re: WBXlog

Posted: 23 Aug 2017, 20:48

by Bigjcc55

I need to get myself on to face book, seems there is plenty of good info on there.

Where do the other two o rings go?

I like the idea of taking the pump face down and using the gasket.

Less likely to leak.

Sent from my iPhone using Tapatalk Pro

Re: WBXlog

Posted: 23 Aug 2017, 21:30

by itchyfeet

other two orings are in place of the other two gaskets, so other side of oil in and out holes and one on the cover face.

Its not all on facebook,

facebook is rubbish for searching back, its very much todays news, here you have a lot of knoledge you can search on, try searching facebook and you get....computers says no results

Re: WBXlog

Posted: 20 Dec 2017, 18:57

by itchyfeet

If anybody is interested Marco Mansi is now selling his three ringed and blueprinted 30mm oil pumps for 120 USD + post, need to be on facebook though.

o ring is recessed more than I did so no mods to oil channels required.

Advert currently on VW T25/T3 VANS AND PARTS FOR SALE group

beware if you buy from USA you will get a VAT bill with a 12 quid handling charge

dunno if this link works

https://www.facebook.com/groups/5605307 ... 2630071971" onclick="window.open(this.href);return false;

oil pump 2

oil pump 2 by

Paul_Barr, on Flickr

oil pump 1

oil pump 1 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 24 Jan 2018, 13:24

by itchyfeet

Engine has been in a year this week and done 3000 miles.

All is well, I never got around to o ringing the oil pump but I will.

Could not resist the sticker

Not the original position which was on the front and on the tailgate but I like it there

112i

112i by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 02 Apr 2018, 11:13

by itchyfeet

Over a year has gone by since I last measured oil pressure and I was a bit disappointed with it so I thought I'd better check it again and I opted for an electric gauge too.

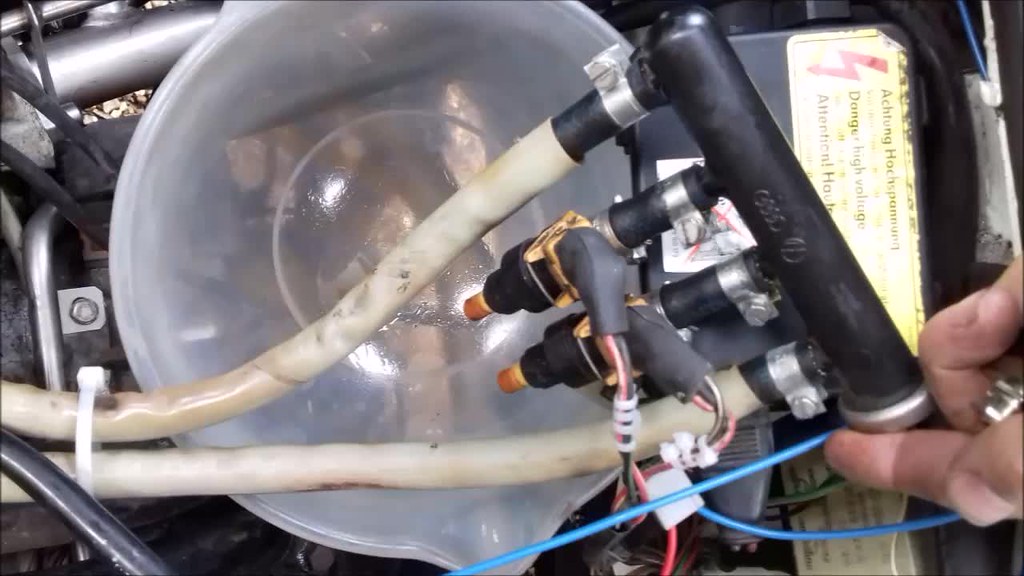

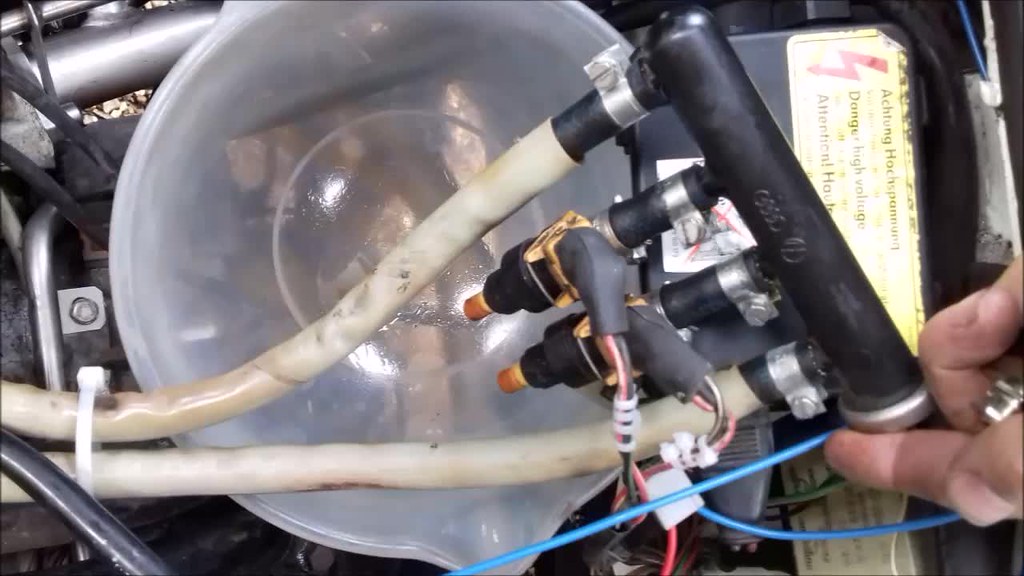

remote T piece in the low pressure switch location

P1090968

P1090968 by

Paul_Barr, on Flickr

made a bracketfor the T piece + sender + oil pressure switch and made the connections in the black box

P1090970

P1090970 by

Paul_Barr, on Flickr

connected my wet gauge to check the electric gauge

P1090984

P1090984 by

Paul_Barr, on Flickr

thermocouple down the oil filler tube, marked it using a spare tube to be sure it was far enough in but not too far to do any harm!

P1090996

P1090996 by

Paul_Barr, on Flickr

P1100002

P1100002 by

Paul_Barr, on Flickr

thats good same as a year ago

idle at 80

P1100004

P1100004 by

Paul_Barr, on Flickr

and then got it up to 100

P1100007

P1100007 by

Paul_Barr, on Flickr

idle at 100

P1100009

P1100009 by

Paul_Barr, on Flickr

still planning the oil pump o ring but just so much else to do

Re: WBXlog

Posted: 07 Apr 2018, 11:12

by itchyfeet

This mornings job is a new set of stainless water pipes, the steel ones are on borrowed time.

oil cooler pipes are fiddly not a great design

P1100081

P1100081 by

Paul_Barr, on Flickr

The stainless tin top pipe behind pulley needed bending too as it rubbed on the pulley ( as would this one) so it looks like this is common

P1100073

P1100073 by

Paul_Barr, on Flickr

I took it off and used a vice so I didn't stress the weld

P1100074

P1100074 by

Paul_Barr, on Flickr

P1100084

P1100084 by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 07 Apr 2018, 13:55

by itchyfeet

This afternoons job was to replace the injector hoses, these are the last bit of old hose left on the van, everythuing has been replaced with the Brickwerks 100% ethanol grade.

P1100087

P1100087 by

Paul_Barr, on Flickr

P1100088

P1100088 by

Paul_Barr, on Flickr

P1100089

P1100089 by

Paul_Barr, on Flickr

P1100090

P1100090 by

Paul_Barr, on Flickr

P1100093

P1100093 by

Paul_Barr, on Flickr

I also did a spray pattern test as described in the VW manual and a leak test, no leakage and spray looks good although may be hard to see ( click for video)

Injector test

Injector test by

Paul_Barr, on Flickr

Re: WBXlog

Posted: 14 Apr 2018, 18:32

by itchyfeet

That oil pressure gauge has got me depressed so I decided to fit the 30mm pump I have had for a year now.

I was going to O ring it but I just have not got around to it so I took the plunge and fitted it as is.

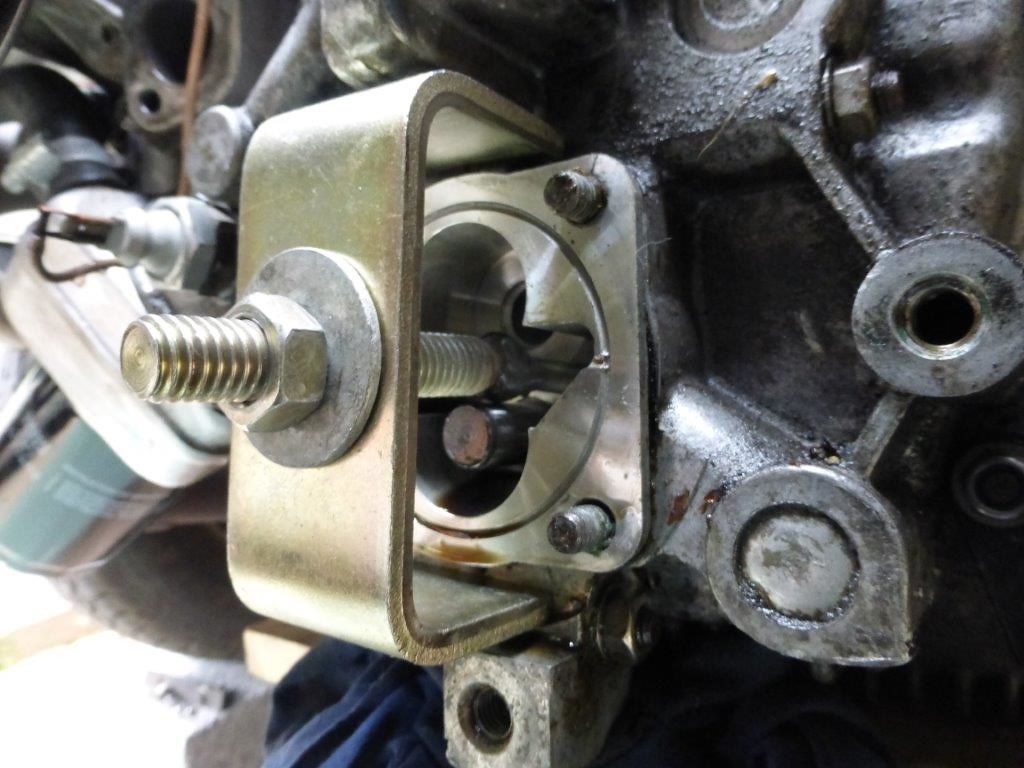

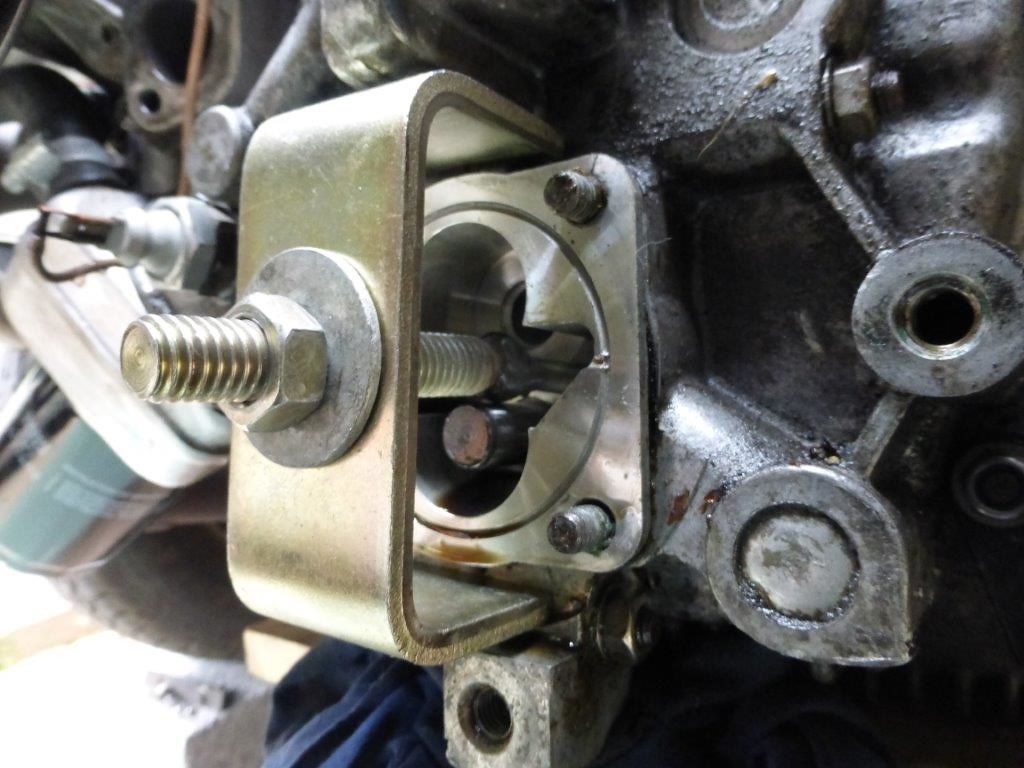

1st job was to weld up my pump puller that I broke

P1100138

P1100138 by

Paul_Barr, on Flickr

silencer off, tin shroud off, support engine, engine bar off, engine cradel off, crank pulley off, water pipes off....

P1100139

P1100139 by

Paul_Barr, on Flickr

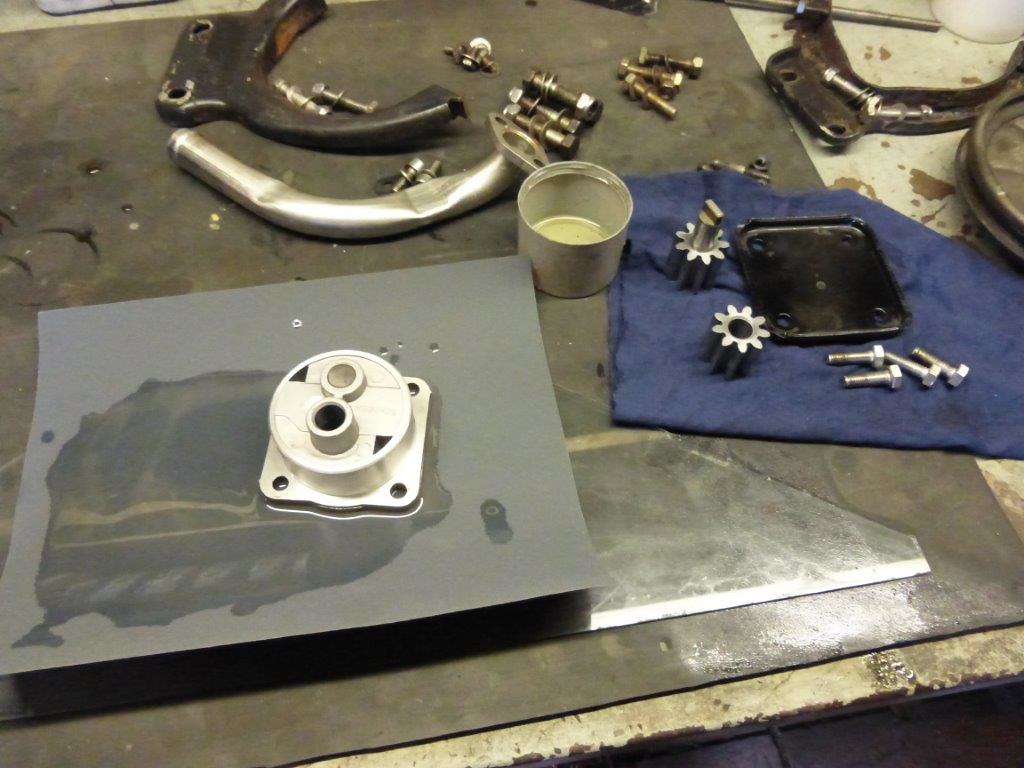

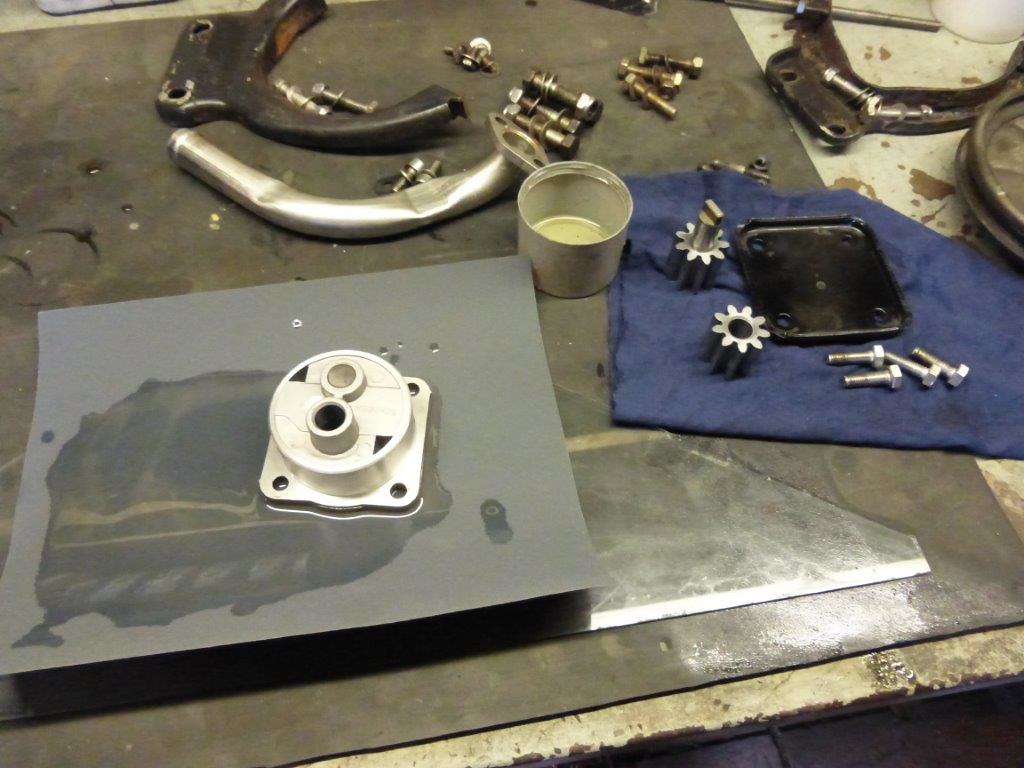

new pump is deeper so need to grind the cover plate down to about 8mm on the vertical sides, then check it fits on a spare case

P1100141

P1100141 by

Paul_Barr, on Flickr

studs are long enough to pull them out 5mm

P1100143

P1100143 by

Paul_Barr, on Flickr

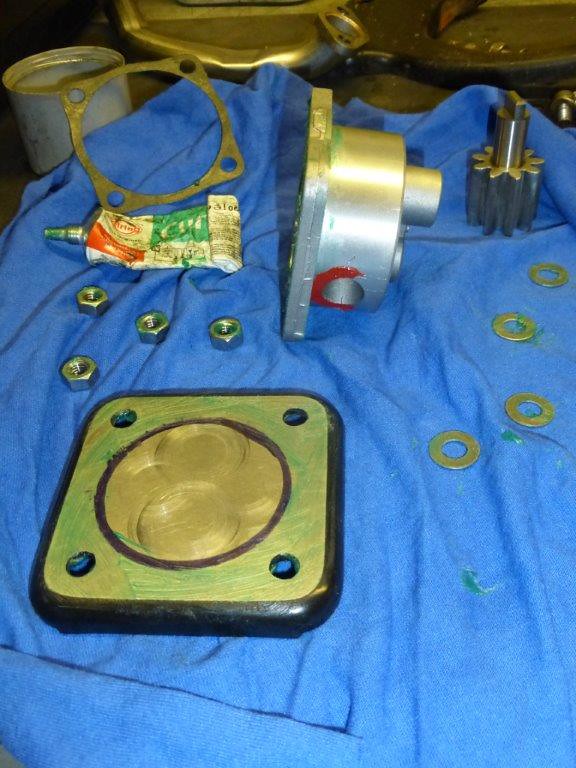

a bit of fettling the pump to get almost zero end float

P1100144

P1100144 by

Paul_Barr, on Flickr

Curil T in place of a gasket and some Dirko HT around the inlet and outlet in horseshoe shapes so the sealant does not end up in the oilway, the Dirko was done yesterday and left 24 hours to set.

P1100146

P1100146 by

Paul_Barr, on Flickr

P1100147

P1100147 by

Paul_Barr, on Flickr

P1100148

P1100148 by

Paul_Barr, on Flickr

P1100151

P1100151 by

Paul_Barr, on Flickr

water pump has play so ideal time to swap it

P1100154

P1100154 by

Paul_Barr, on Flickr

all back took longer than expected because I just had to paint stuff

( OCD?)

P1100160

P1100160 by

Paul_Barr, on Flickr

please with the results. this was 2.5bar

P1100162 30mm pump

P1100162 30mm pump by

Paul_Barr, on Flickr

this was 1.5 bar

P1100168 30mm pump

P1100168 30mm pump by

Paul_Barr, on Flickr