Page 13 of 15

Re: WBXmayo

Posted: 25 Jan 2018, 19:06

by itchyfeet

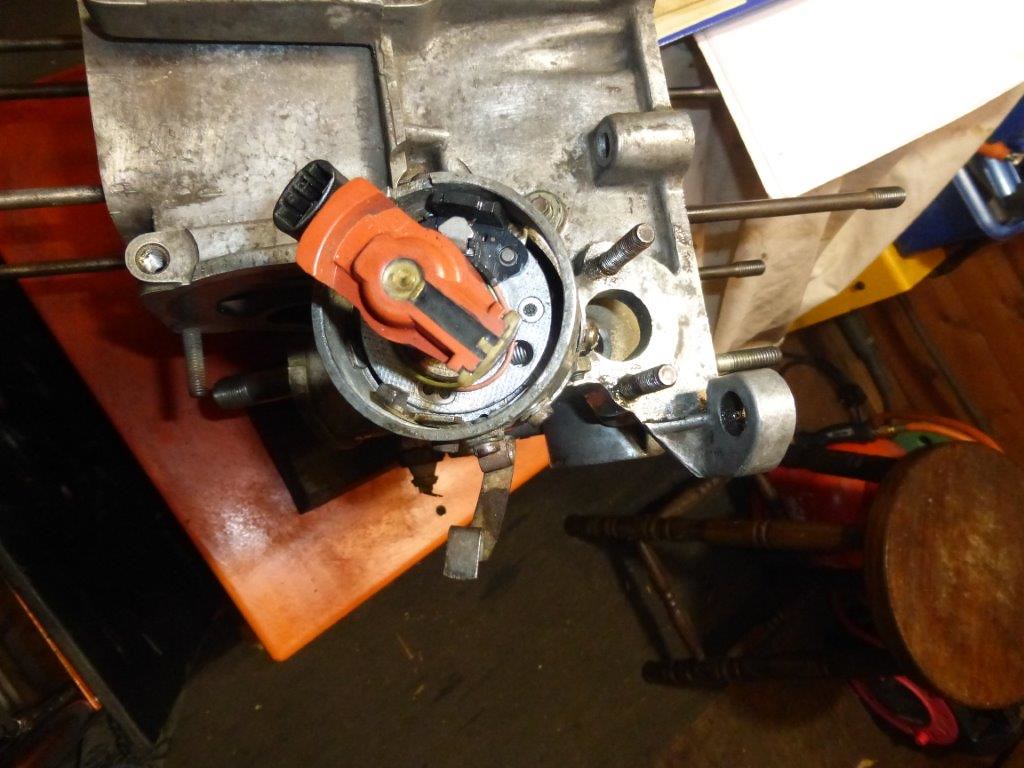

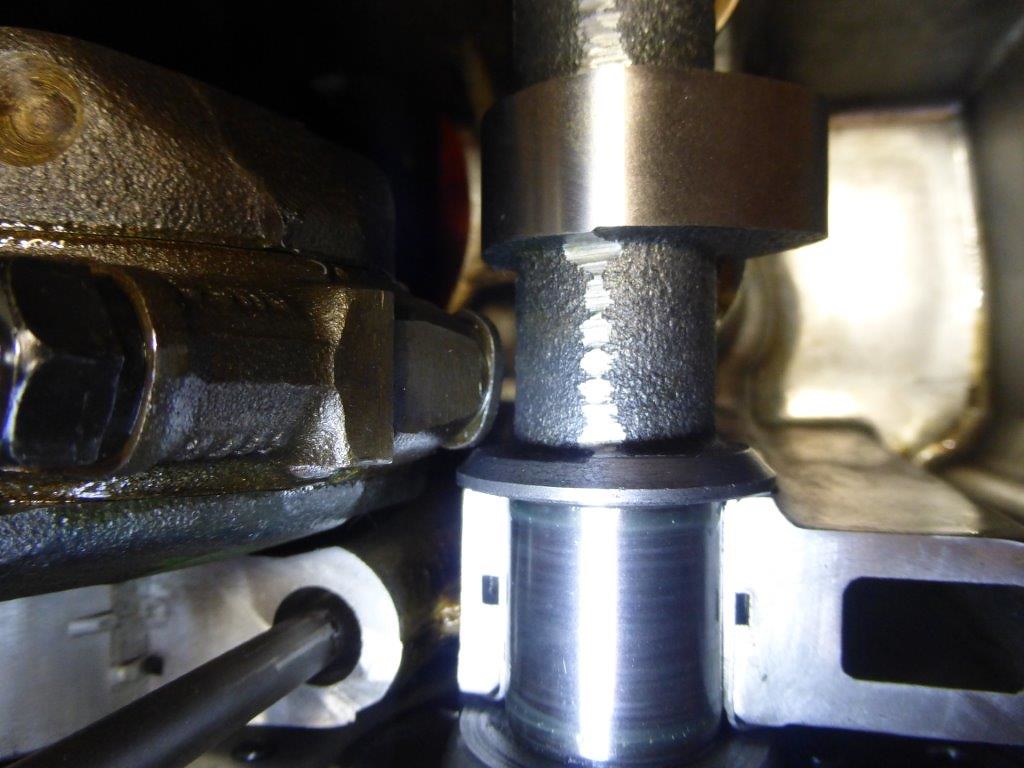

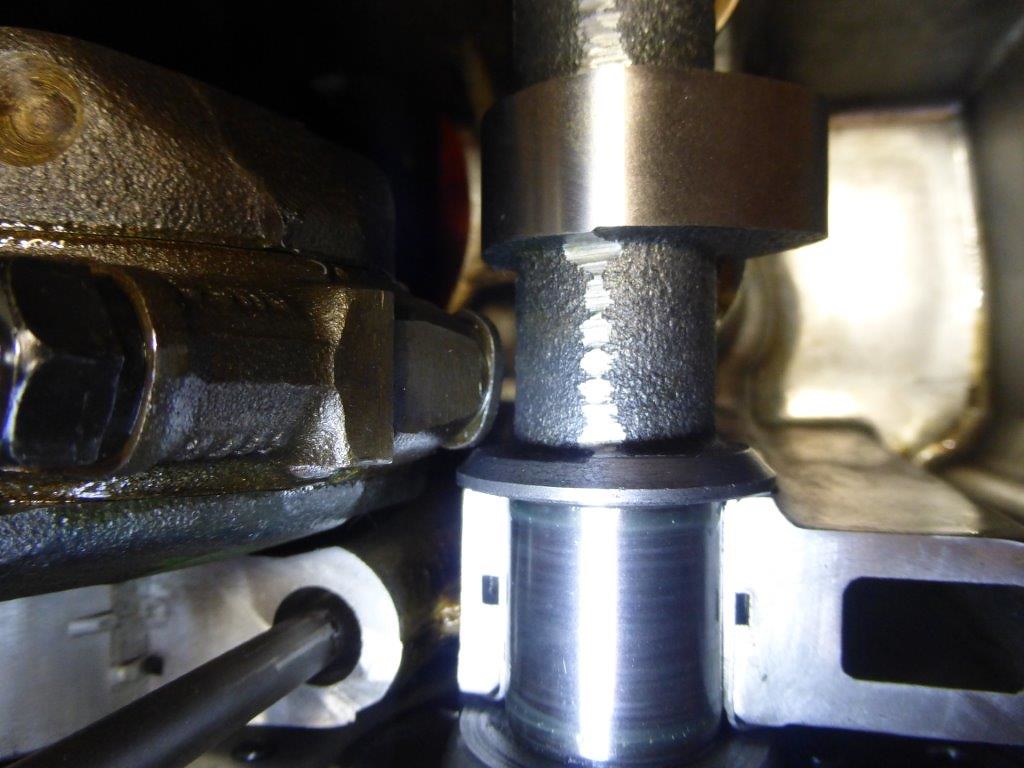

Its clear that the problem is a little wear in the case which has made a small step, so I used some 1200 grit wet and dry to take the edge off and now it slides in and out much better.

P1090293

P1090293 by

Paul_Barr, on Flickr

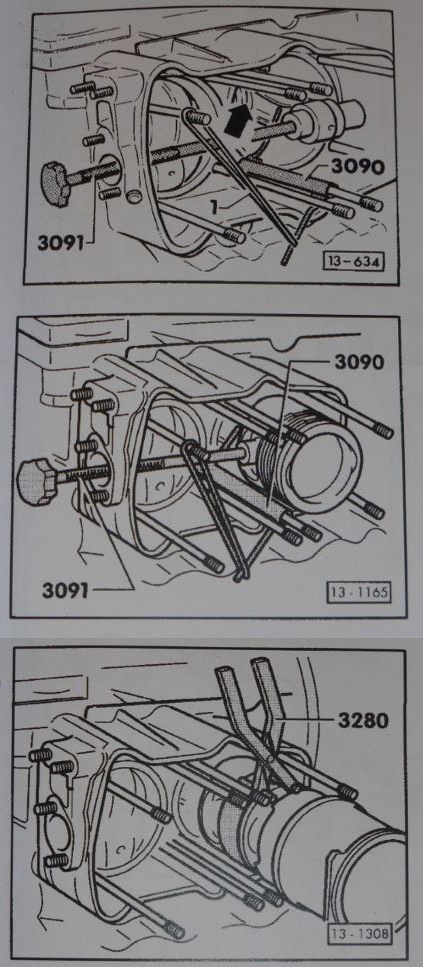

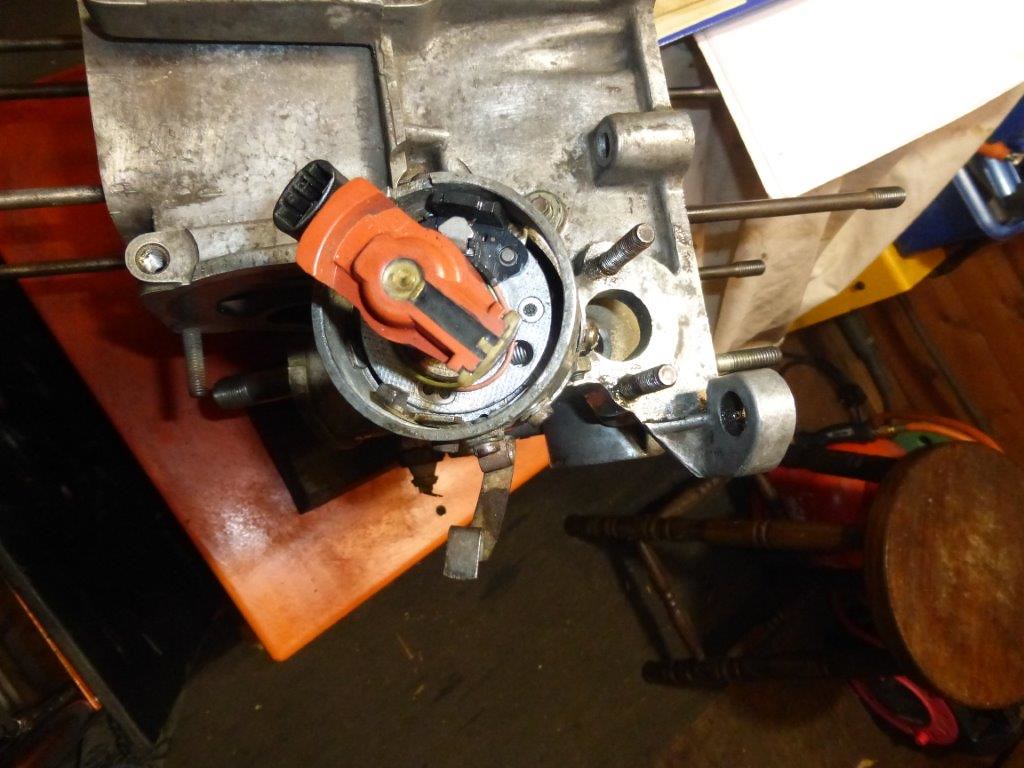

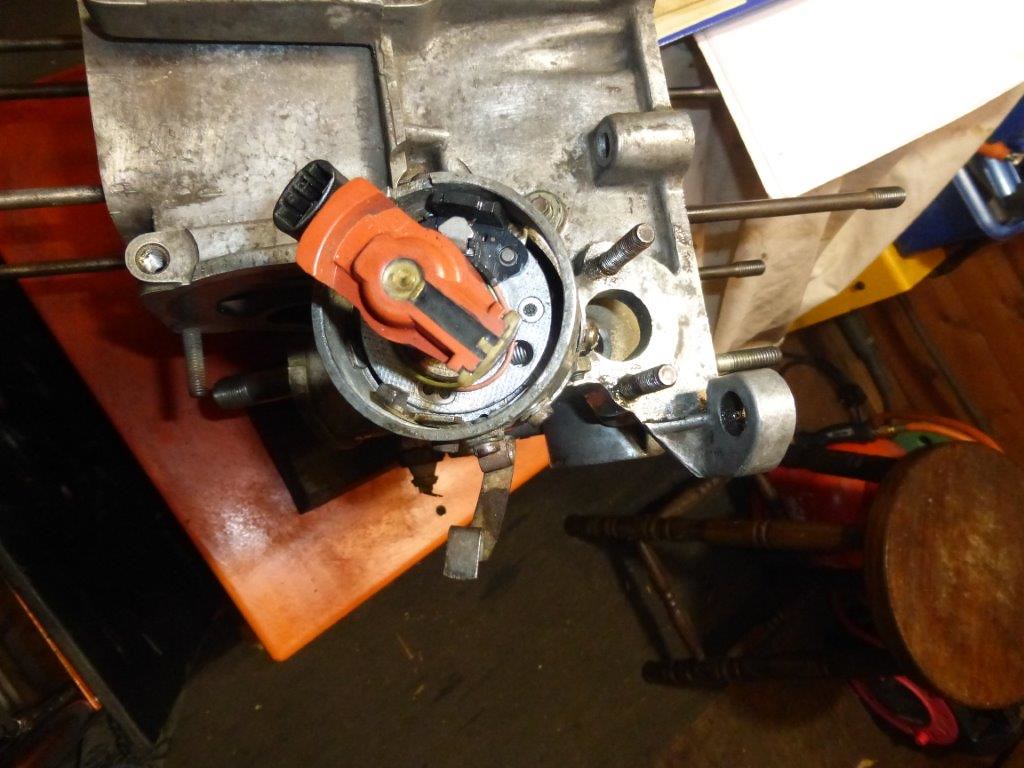

next is to work out where it should be set, Haynes and VW seem to disagree, I think the confusion is because when you insert it with crank in place it rotates so there is a start position and a final position.

P1090295

P1090295 by

Paul_Barr, on Flickr

Hays says

P1090296

P1090296 by

Paul_Barr, on Flickr

VW says

P1090303

P1090303 by

Paul_Barr, on Flickr

it's really not important other than clearance of the vac can so I checked the DJ setup which is more busy and I opted for the Haynes as a final position.

P1090307

P1090307 by

Paul_Barr, on Flickr

checked the new KS tappets slid easily through the bores

P1090308

P1090308 by

Paul_Barr, on Flickr

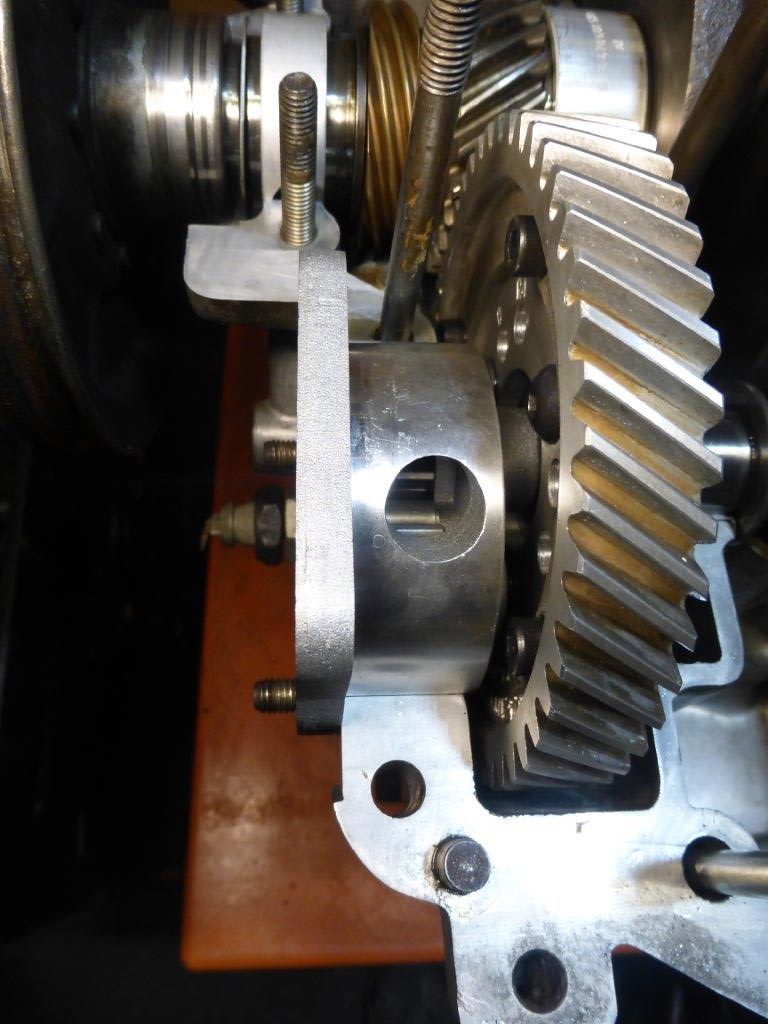

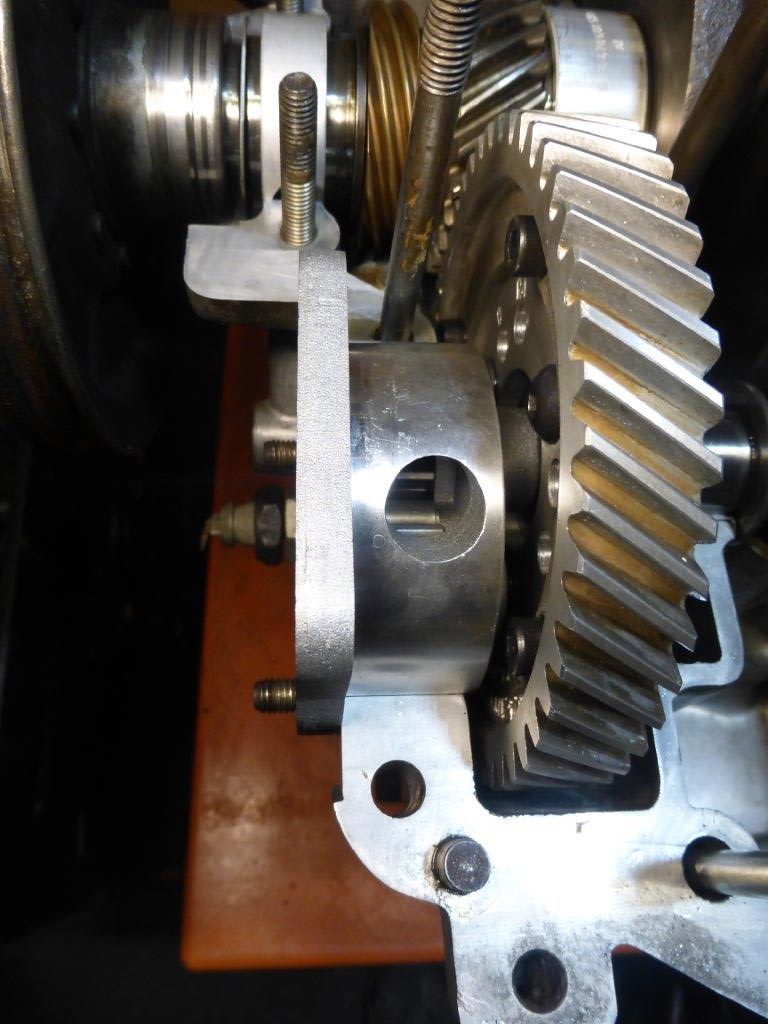

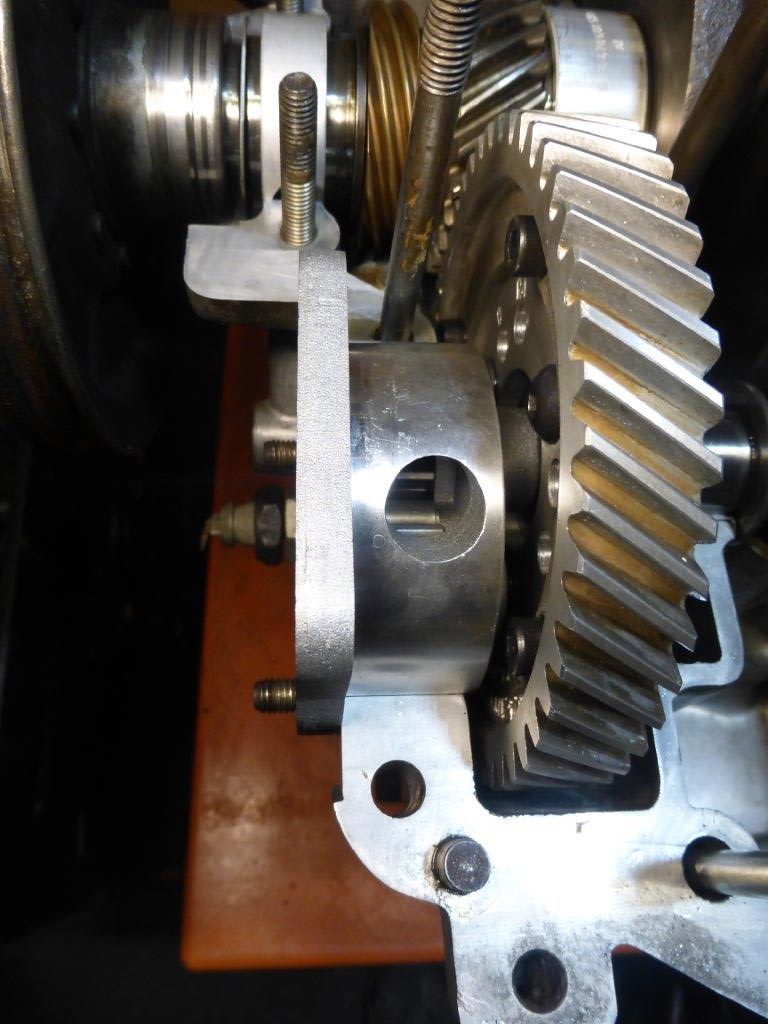

dropped the crank in and aligned the dizzy gear

P1090318

P1090318 by

Paul_Barr, on Flickr

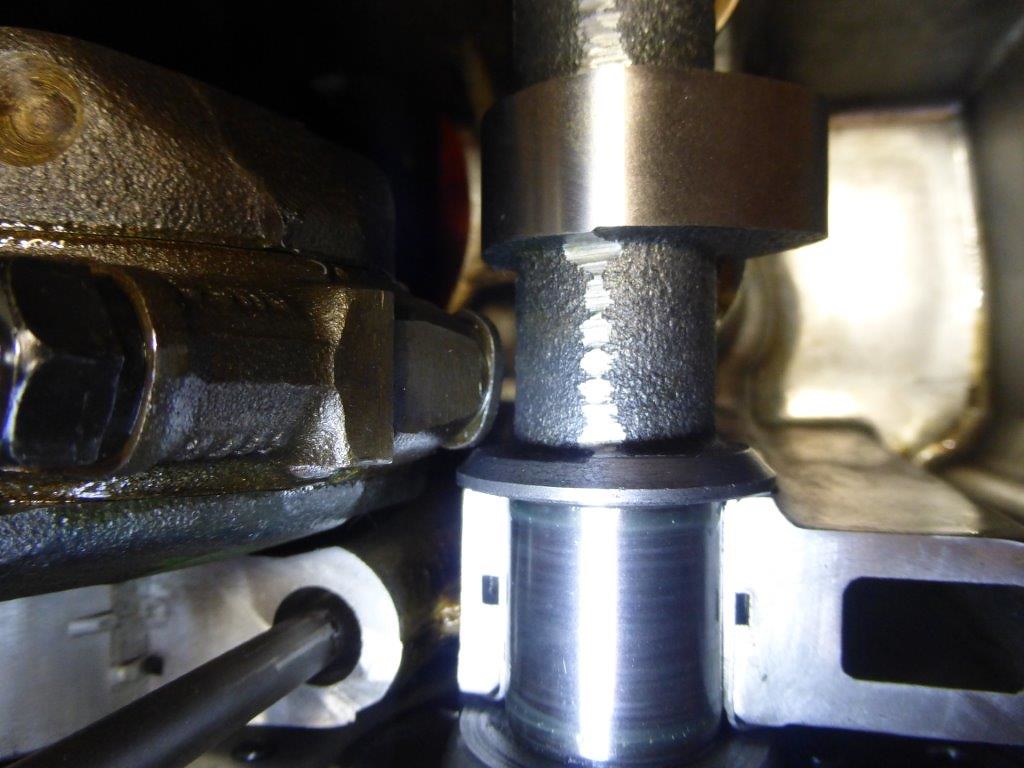

didn't check this earlier because it was clearly good can't even get a 0.05 in

P1090313

P1090313 by

Paul_Barr, on Flickr

cam in

P1090319

P1090319 by

Paul_Barr, on Flickr

amazing how close some parts are

P1090321

P1090321 by

Paul_Barr, on Flickr

Air cooled oil pump to match the 3 bolt cam, all looks good ( this will get o ringed)

P1090324

P1090324 by

Paul_Barr, on Flickr

P1090317

P1090317 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 25 Jan 2018, 19:14

by Oldiebut goodie

Patience of Job!

Re: WBXmayo

Posted: 26 Jan 2018, 16:57

by itchyfeet

Assembled the case to make sure it turns and nothing is wrong.

Yes I remembered to fit the cam bearings and the shells of crank bearing 2

P1090327

P1090327 by

Paul_Barr, on Flickr

At the recommendation of Marco Mansi I have opted for some molybdenum disulfide on the main high tensile studs, I have gone for dry spray.

P1090334

P1090334 by

Paul_Barr, on Flickr

all mating surfaces, nuts and washers and cam cap degreased with meths ready for closing the case.

P1090333

P1090333 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 27 Jan 2018, 13:32

by itchyfeet

Curil T on, I don't like this stuff much it's hard to get a thin layer, you get thick or patchy.

P1090335

P1090335 by

Paul_Barr, on Flickr

first nut

P1090344

P1090344 by

Paul_Barr, on Flickr

The the M10s and then the rest of the M8s

P1090345

P1090345 by

Paul_Barr, on Flickr

P1090347

P1090347 by

Paul_Barr, on Flickr

P1090346

P1090346 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 28 Jan 2018, 17:18

by itchyfeet

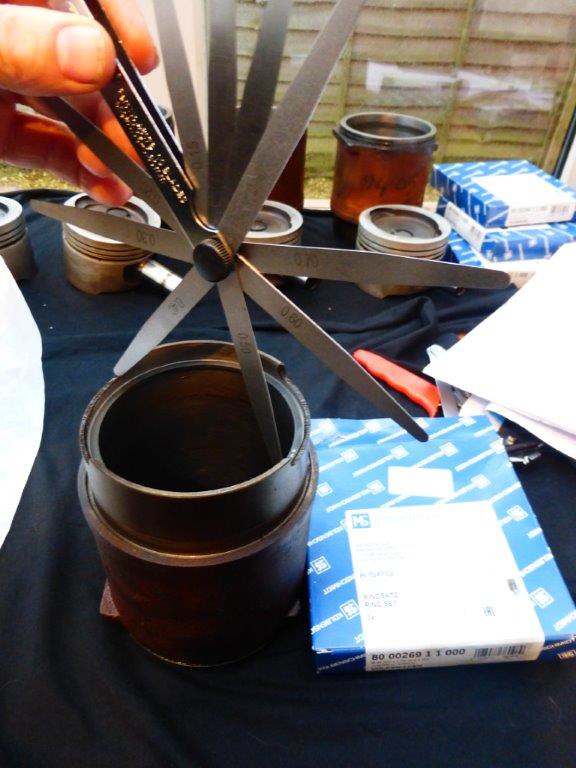

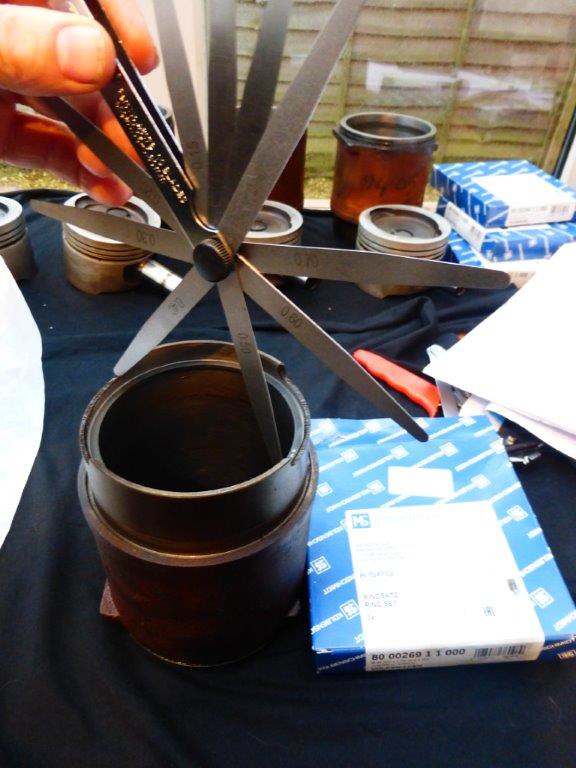

checked ring gaps

P1090348

P1090348 by

Paul_Barr, on Flickr

P1090349

P1090349 by

Paul_Barr, on Flickr

rings on ( top one needs a tool as its strong)

P1090350

P1090350 by

Paul_Barr, on Flickr

ring compressior on tight, oiled barrel

P1090362

P1090362 by

Paul_Barr, on Flickr

P1090363

P1090363 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 29 Jan 2018, 08:44

by ajsimmo

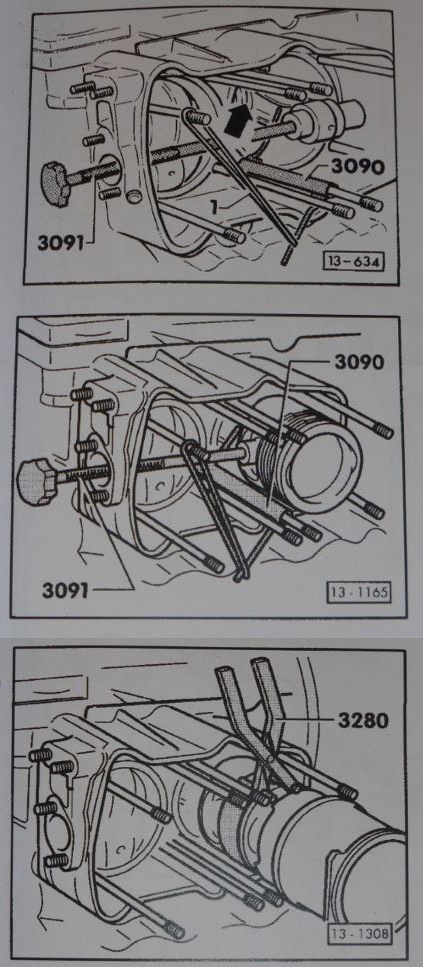

Interesting that you put pistons in from the top. I have tried it, but it's not easy to do smoothly. Ialways put them in from the bottom, as per VW manuals. There is a chamfer to help the rings transition (or is it implementation?) into the bore. The cut outs seem to help too.

Sent from my ONEPLUS A3003 using Tapatalk

Re: WBXmayo

Posted: 29 Jan 2018, 10:36

by colinthefox

Oh I do love a good engine rebuild thread. Thanks Itchy!

ajsimmo wrote:..................... transition (or is it implementation?)............

Classsic.

Re: WBXmayo

Posted: 29 Jan 2018, 11:53

by itchyfeet

ajsimmo wrote:Interesting that you put pistons in from the top. I have tried it, but it's not easy to do smoothly. Ialways put them in from the bottom, as per VW manuals. There is a chamfer to help the rings transition (or is it implementation?) into the bore. The cut outs seem to help too.

Sent from my ONEPLUS A3003 using Tapatalk

Not tried going in the bottom myself

Another case of me not reading the maual

as long as the co pressor is tight they go in ok but you need to go in quick

Re: WBXmayo

Posted: 29 Jan 2018, 15:48

by 937carrera

Reminds me of the first 412 engine rebuild I did (many moons ago). In my case I assembled the pistons first then slid the barrels onto the pistons using a big, well lubricated, jubilee clip as a piston ring compressor. My toolkit was nowhere near as extensive back in those days

Always more than one way to skin a cat, and as I have a CU engine to rebuild this is great prep

Re: WBXmayo

Posted: 29 Jan 2018, 16:05

by itchyfeet

VW manual says put pistons on con rods then barrels on so maybe that's why they go in from the bottom.

Piston install

Piston install by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 29 Jan 2018, 18:50

by itchyfeet

Well you learn something everyday, it seems 2.1s always had 10mm tappet screws, been through the collection and I have a set of rocker shafts with 10mm screws

I'm sure there must be 2.1's out there with 9mm screws after rebuilds, I have certainly stripped a DJ with 9mm rocker screws.

P1090372

P1090372 by

Paul_Barr, on Flickr

just looked back at WBXlog DJ build pics which had the heads from Mayo engine and they are 10mm

P1060791

P1060791 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 30 Jan 2018, 22:03

by itchyfeet

I wanted to O ring the pump but the 3 bolt cam needs an Aircooled pump and not only does it have a bigger port but it's not so deep.

No chance of getting an o ring groove in just over 3mm

P1090404

P1090404 by

Paul_Barr, on Flickr

P1090405

P1090405 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 31 Jan 2018, 19:41

by itchyfeet

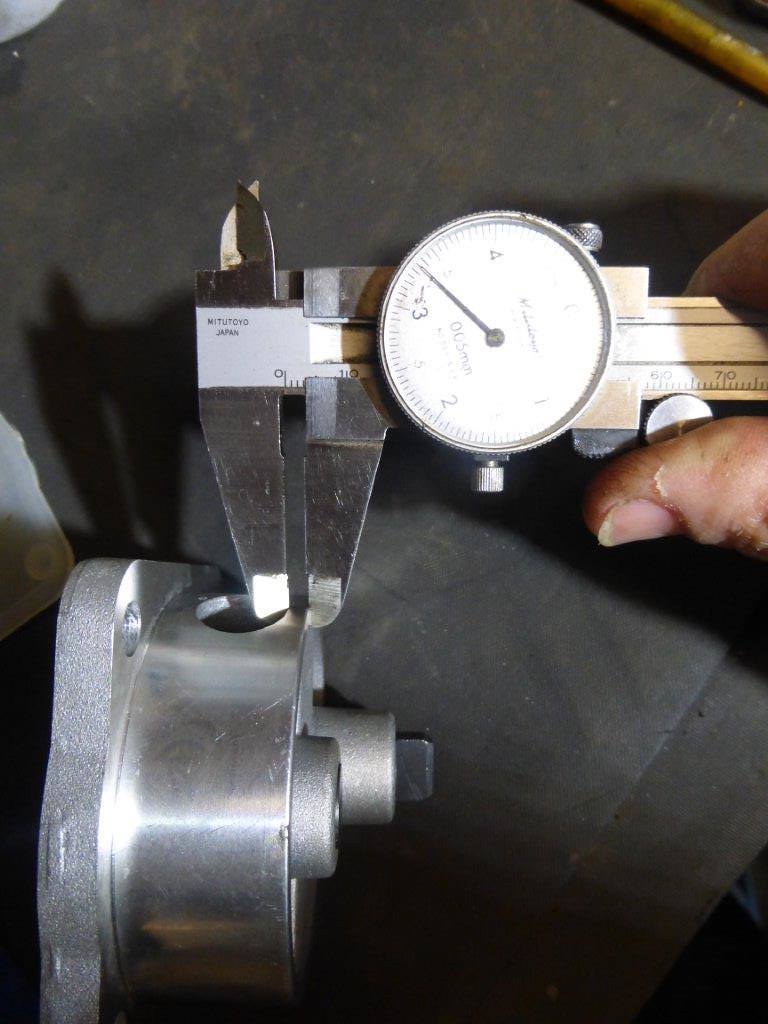

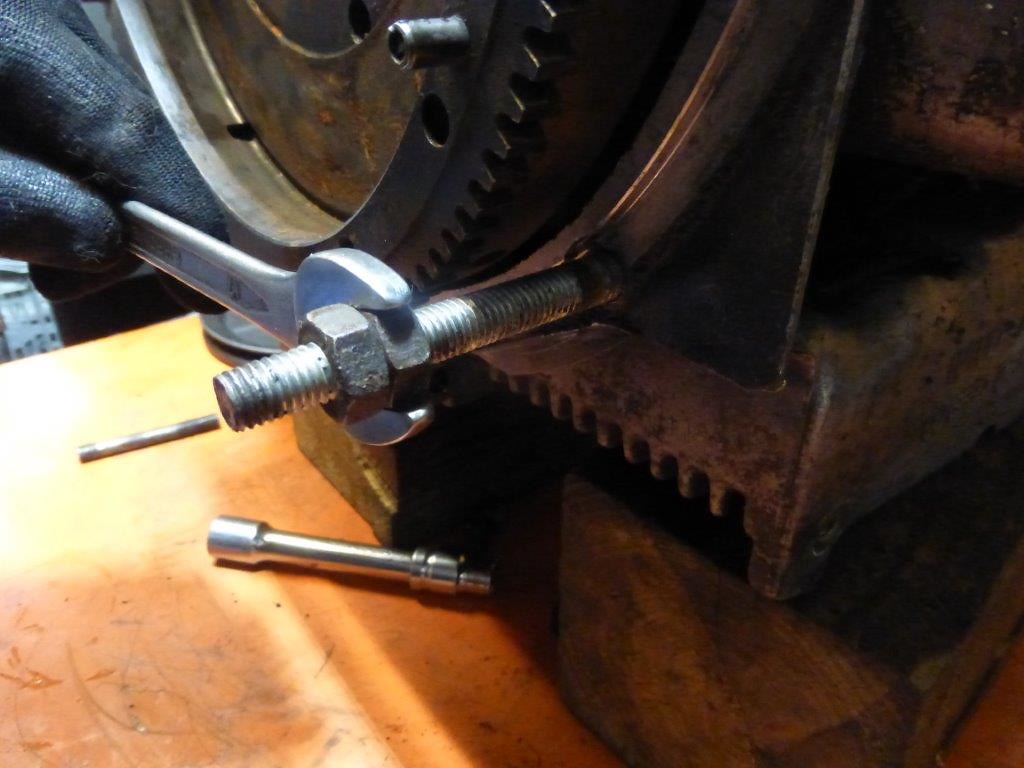

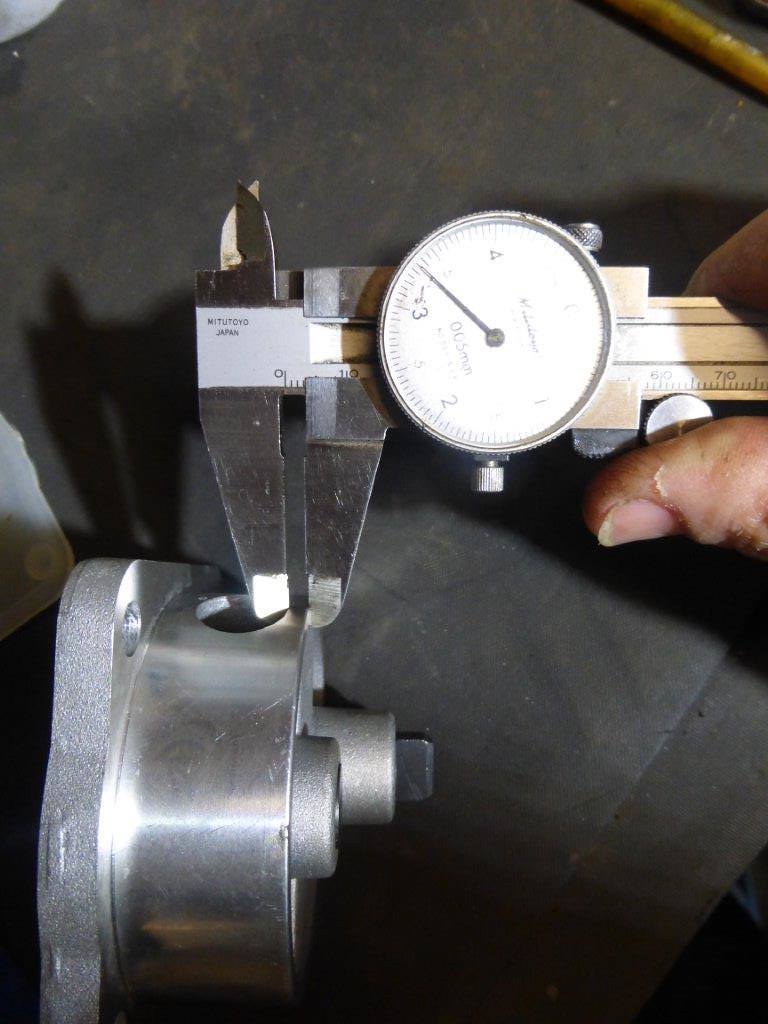

Not so speedi sleeve fitted tonight, Most flywheels are now grooved and will leak oil past seals if not sleeved.

P1090408

P1090408 by

Paul_Barr, on Flickr

measure up

P1090410

P1090410 by

Paul_Barr, on Flickr

Engineers blue ( or a marker pen) and scribe the depth

P1090412

P1090412 by

Paul_Barr, on Flickr

dermel in a vice with a crude depth gauge and cutting disk

P1090416

P1090416 by

Paul_Barr, on Flickr

clean up the burr

P1090419

P1090419 by

Paul_Barr, on Flickr

cut the rim

P1090420

P1090420 by

Paul_Barr, on Flickr

clean with meths, some oil resistant high temp Dirko

P1090425

P1090425 by

Paul_Barr, on Flickr

hammer it on

P1090426

P1090426 by

Paul_Barr, on Flickr

peel off the rim

P1090430

P1090430 by

Paul_Barr, on Flickr

file the edge off carefully making sure it's under flush

P1090431

P1090431 by

Paul_Barr, on Flickr

ready to set end float

P1090439

P1090439 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 01 Feb 2018, 18:58

by itchyfeet

Started with a new thrust washer ( they come as a pair so one new on inside already) a 0.4mm large diameter shim and one 0.32mm shim

P1090441

P1090441 by

Paul_Barr, on Flickr

this plate stops the flywheel rotating when you do the measurement which makes it inaccurate.

P1090448

P1090448 by

Paul_Barr, on Flickr

about 0.35mm so I'm aiming for minimum float which is 0.07mm so I need a 0.28mm shim which I don't have ( all my shims are larger)

P1090444

P1090444 by

Paul_Barr, on Flickr

removed new thrust washer and replaced with a used one which give me some and then fitted some other shims to get the 0.07mm

P1090445

P1090445 by

Paul_Barr, on Flickr

not spot on 0.1mm

P1090446

P1090446 by

Paul_Barr, on Flickr

remeasure and swapped the smaller shims for very slightly bigger ones

P1090447

P1090447 by

Paul_Barr, on Flickr

spot on

P1090449

P1090449 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 01 Feb 2018, 19:03

by itchyfeet

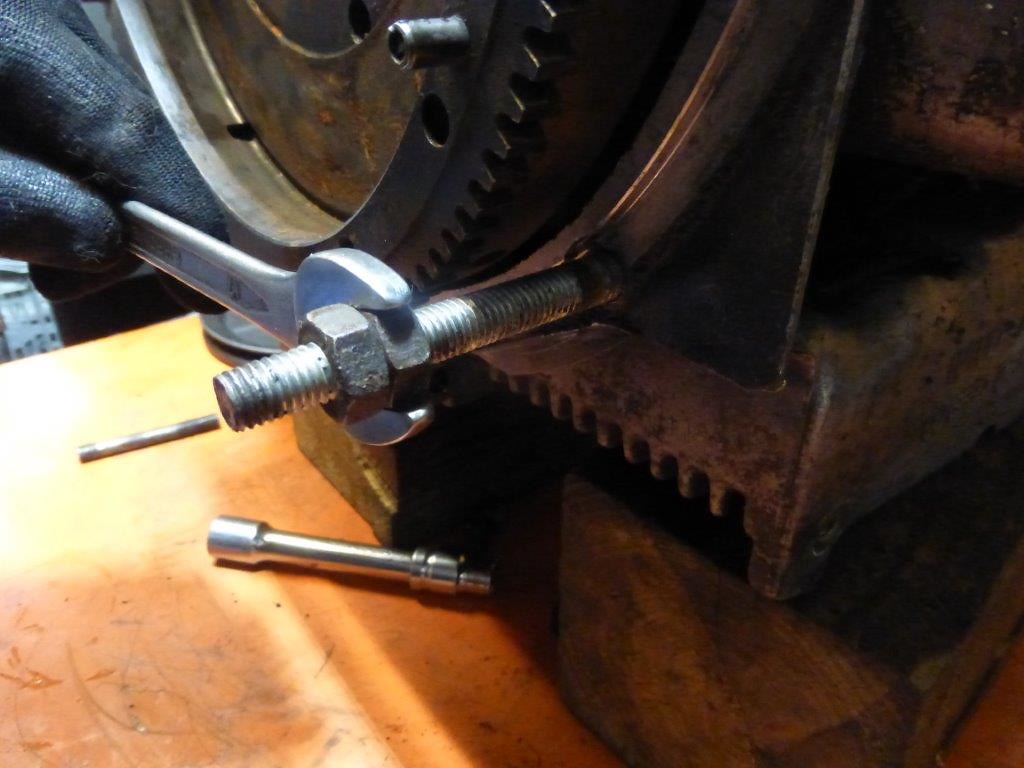

I guess this was once on an auto, studs are not VW they are a bit of studding cut to length and threads in poor condition

pulled them out and replaced with studs from another spare case I had

P1090452

P1090452 by

Paul_Barr, on Flickr

Thread locked in to 75mm for a manual gearbox.

P1090454

P1090454 by

Paul_Barr, on Flickr

P1090293 by Paul_Barr, on Flickr

P1090293 by Paul_Barr, on Flickr P1090295 by Paul_Barr, on Flickr

P1090295 by Paul_Barr, on Flickr P1090296 by Paul_Barr, on Flickr

P1090296 by Paul_Barr, on Flickr P1090303 by Paul_Barr, on Flickr

P1090303 by Paul_Barr, on Flickr P1090307 by Paul_Barr, on Flickr

P1090307 by Paul_Barr, on Flickr P1090308 by Paul_Barr, on Flickr

P1090308 by Paul_Barr, on Flickr P1090318 by Paul_Barr, on Flickr

P1090318 by Paul_Barr, on Flickr P1090313 by Paul_Barr, on Flickr

P1090313 by Paul_Barr, on Flickr P1090319 by Paul_Barr, on Flickr

P1090319 by Paul_Barr, on Flickr

P1090321 by Paul_Barr, on Flickr

P1090321 by Paul_Barr, on Flickr P1090324 by Paul_Barr, on Flickr

P1090324 by Paul_Barr, on Flickr P1090317 by Paul_Barr, on Flickr

P1090317 by Paul_Barr, on Flickr P1090293 by Paul_Barr, on Flickr

P1090293 by Paul_Barr, on Flickr P1090295 by Paul_Barr, on Flickr

P1090295 by Paul_Barr, on Flickr P1090296 by Paul_Barr, on Flickr

P1090296 by Paul_Barr, on Flickr P1090303 by Paul_Barr, on Flickr

P1090303 by Paul_Barr, on Flickr P1090307 by Paul_Barr, on Flickr

P1090307 by Paul_Barr, on Flickr P1090308 by Paul_Barr, on Flickr

P1090308 by Paul_Barr, on Flickr P1090318 by Paul_Barr, on Flickr

P1090318 by Paul_Barr, on Flickr P1090313 by Paul_Barr, on Flickr

P1090313 by Paul_Barr, on Flickr P1090319 by Paul_Barr, on Flickr

P1090319 by Paul_Barr, on Flickr P1090321 by Paul_Barr, on Flickr

P1090321 by Paul_Barr, on Flickr P1090324 by Paul_Barr, on Flickr

P1090324 by Paul_Barr, on Flickr P1090317 by Paul_Barr, on Flickr

P1090317 by Paul_Barr, on Flickr