Page 9 of 15

Re: WBXmayo

Posted: 11 Dec 2017, 20:00

by 300CE

itchyfeet wrote:That or I weld a few old cases together and make a V12

Now that I’d like to see!

Re: WBXmayo

Posted: 12 Dec 2017, 18:46

by itchyfeet

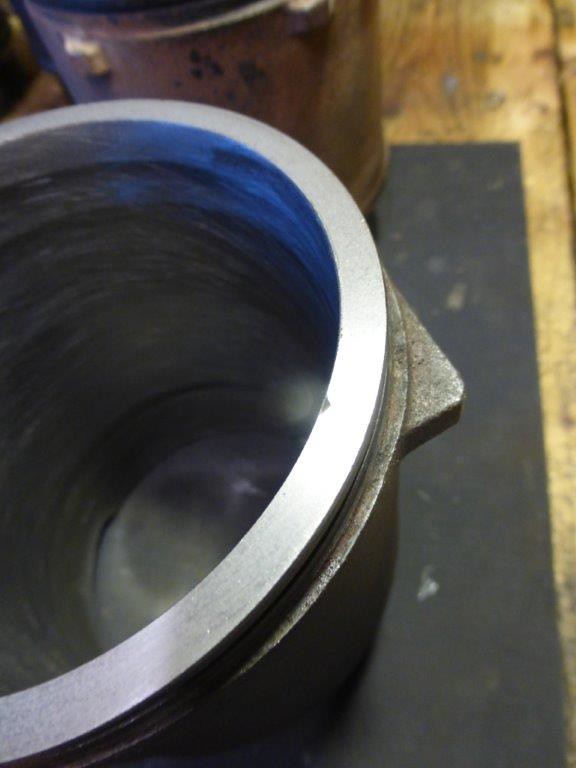

Dug them all out, the good news is I have some better that mayo engine had.

Going to hone them, clean the seal recesses and then decide which to use.

P1080932

P1080932 by

Paul_Barr, on Flickr

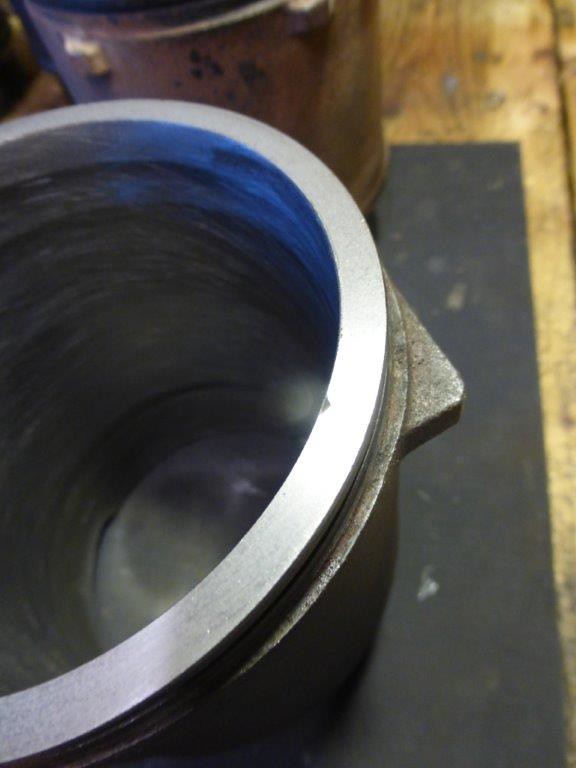

Some hone up like this, I don't really know if it's a problem of not

P1080931

P1080931 by

Paul_Barr, on Flickr

Its a shame a few that are really good inside have damage to the compression sealing surface presumably by some cack handed engine rebuilder in the past, I don't think I would risk it.

P1050648

P1050648 by

Paul_Barr, on Flickr

Never seen a cracked one before, this had this piston

P1080930

P1080930 by

Paul_Barr, on Flickr

20170907_174246

20170907_174246 by

Paul_Barr, on Flickr

Got a scored one from a circlip that broke free, I think somebody put it back like this because the circlip isn't missing anymore!!!

P1080935

P1080935 by

Paul_Barr, on Flickr

also as well as some that have just got pitted from rust

Re: WBXmayo

Posted: 13 Dec 2017, 18:59

by itchyfeet

Honed them all now , removed all old orings, wire brushed the top seal and used wet and dry 600 grit on the sealing surface to clean it up.

Honed with brake fluid ( because you want to cut not slide) but brake fluid is hydroscopic so they must be oiled after or they soon rust.

P1080938

P1080938 by

Paul_Barr, on Flickr

20171213_183201

20171213_183201 by

Paul_Barr, on Flickr

It's not until you hone that you see the real condition, these are from mayo engine, it was probably only driven 10 miles with mayo in it but you can really see the damage done.

P1080940

P1080940 by

Paul_Barr, on Flickr

P1080939

P1080939 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 14 Dec 2017, 08:17

by 300CE

Are those really scrap now Paul or can something be done to rectify?

Re: WBXmayo

Posted: 14 Dec 2017, 09:30

by itchyfeet

300CE wrote:Are those really scrap now Paul or can something be done to rectify?

I'm sure you could refit them and I'm sure budget engine rebuilders do, engine will run fine, its not a race engine but it has to be loosing a bit of compression.

the scratches are not deep but honing really showes up inperfections.

As this is a Higher compression DJ I'd rather pick the best I have.

Re: WBXmayo

Posted: 14 Dec 2017, 19:28

by itchyfeet

After another couple of hours honing and inspecting I have four winners.

Barrels

94.03

94.04

94.05

94.04

So paring with pistons we are all well under the 0.2mm wear limit

No1 93.95 / 94.04 = 0.09

No2 93.93 / 94.04 = 0.11

No3 93.90 /94.03 = 0.13

No4 93.95 /94.05 = 0.10

I have two other DJ pistons I'm going to dig out and see if I can improve on the 93.90 one.

closer tolerances mean less ring gap too so better compression.

P1080944

P1080944 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 14 Dec 2017, 20:11

by 300CE

itchyfeet wrote:300CE wrote:Are those really scrap now Paul or can something be done to rectify?

I'm sure you could refit them and I'm sure budget engine rebuilders do, engine will run fine, its not a race engine but it has to be loosing a bit of compression.

the scratches are not deep but honing really showes up inperfections.

As this is a Higher compression DJ I'd rather pick the best I have.

Re: WBXmayo

Posted: 17 Dec 2017, 17:42

by itchyfeet

Dug out my spare DJ pistons and they are both a different weight group, one is 0.02mm bigger but it's not worth swapping it.

P1090018

P1090018 by

Paul_Barr, on Flickr

found a gudgeon pin that was more like the right weight

P1090020

P1090020 by

Paul_Barr, on Flickr

checked the con rods just in case somebody swapped a gudgeon pin to offset a heavy con rod but no they are all within a couple of grams

P1090021

P1090021 by

Paul_Barr, on Flickr

These are stretch bolts ( note long threads) and onetime use so I have removed a set of non stretch ( short threads) from an early engine that I'm going to fit.

P1090023

P1090023 by

Paul_Barr, on Flickr

reamed the burrs so that the pins slide in

P1090024

P1090024 by

Paul_Barr, on Flickr

Cleaned up the pistons with wet and dry, paraffin, carb cleaner and a toothbrush ready for ring measuring/checking/fitting

P1090027

P1090027 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 17 Dec 2017, 18:17

by 937carrera

Are you going to remove some material to balance the piston weights up - not necessary, but you seem to be taking quite a lot of care?

Re: WBXmayo

Posted: 17 Dec 2017, 18:49

by itchyfeet

937carrera wrote:Are you going to remove some material to balance the piston weights up - not necessary, but you seem to be taking quite a lot of care?

Nope, 10grams is VW spec I'm well under that, it's not a race engine but I try to keep inside VW spec.

Re: WBXmayo

Posted: 18 Dec 2017, 19:57

by itchyfeet

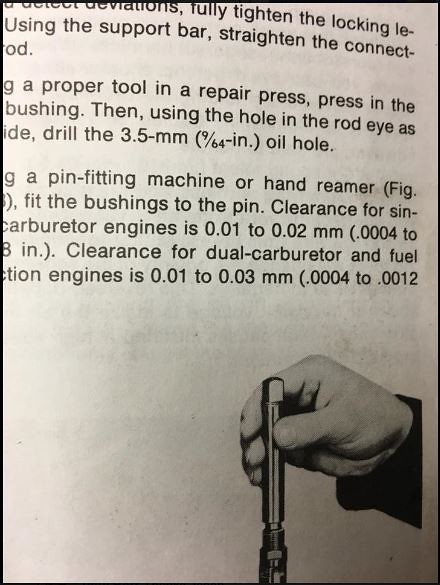

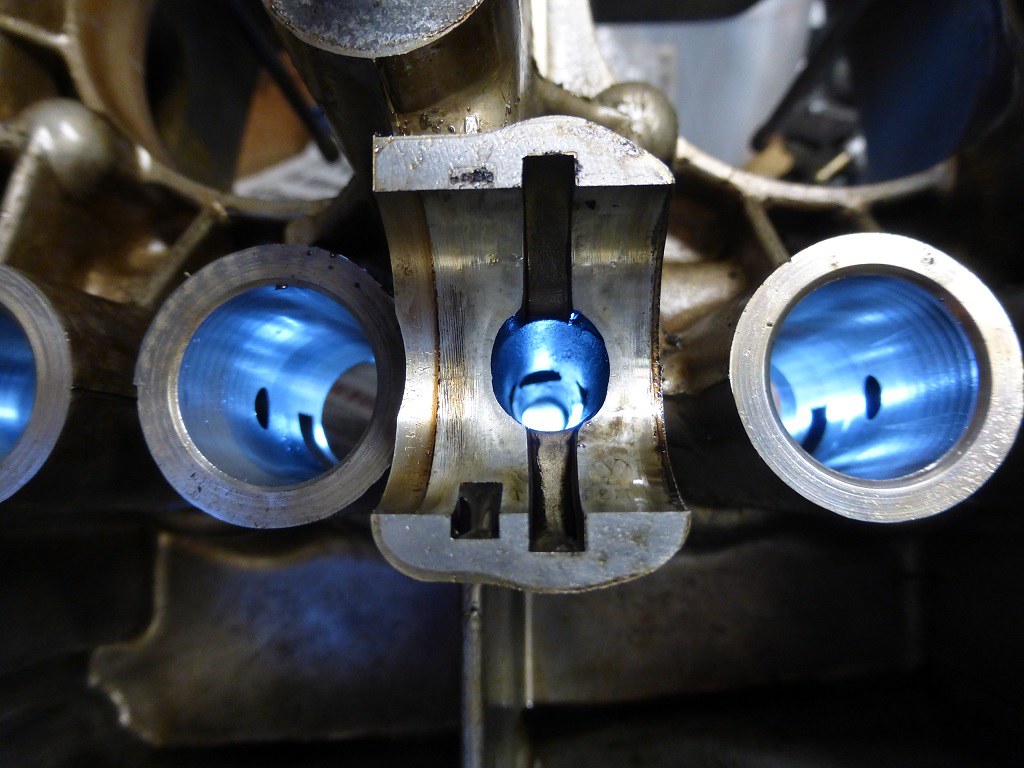

checked little end bearings with the piston pins, this isn't in the VW manual there seem to be no specs of wear limits I can find.

I have read a general rule of thumb is it should not fall out when oiled and pushed into the con rod and held vertically, there should be no play that can be felt.

This says to me these rods have been changed when it was last rebuilt or the bushes were replaced and reamed, most I have seen removed from engines pins fall out and you can feel play.

P1090041

P1090041 by

Paul_Barr, on Flickr

swapped the bolts over to standard, the nuts are different on standard too they have a reduced contact area

P1090042

P1090042 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 21 Dec 2017, 18:21

by itchyfeet

cam adapters arrived today from USA

they spent more time getting from UK to me than USA to UK

When anything arrives from USA it has to go through customs then you get sent a bill for VAT + import duty with a handling fee ( about 12 quid handling fee for parcel force) once you pay it gets delivered.

I bought a couple for other members on here also to get the price down sharing the postage.

P1090044

P1090044 by

Paul_Barr, on Flickr

Unfortunately Royal mail took 3 weeks to deliver my old cam to Newman cams so they have only just got it so no cam for a few more weeks because they are on shutdown next week.

I still have loads of prep to do so next is the heads.

These are two used AMC heads that I bought and bartered, the valves are not VW and so they are going to get swapped out with valves from some old scrap heads I have...assuming I find nothing else wrong with them.

P1090046

P1090046 by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 22 Dec 2017, 17:39

by itchyfeet

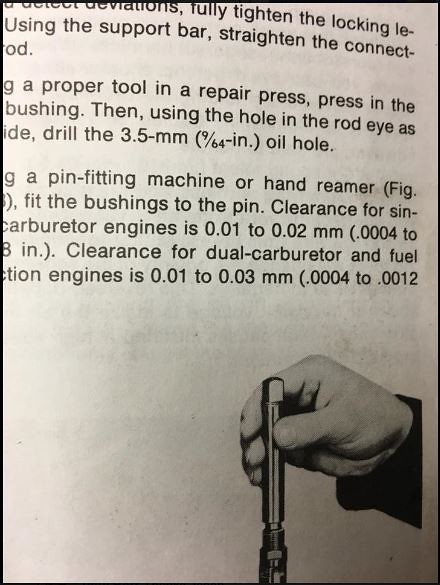

Just got this extract from type 4 manual for little end clearances, type 4 being the same pin size...interesting

Type 4 little end spec

Type 4 little end spec by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 22 Dec 2017, 17:58

by itchyfeet

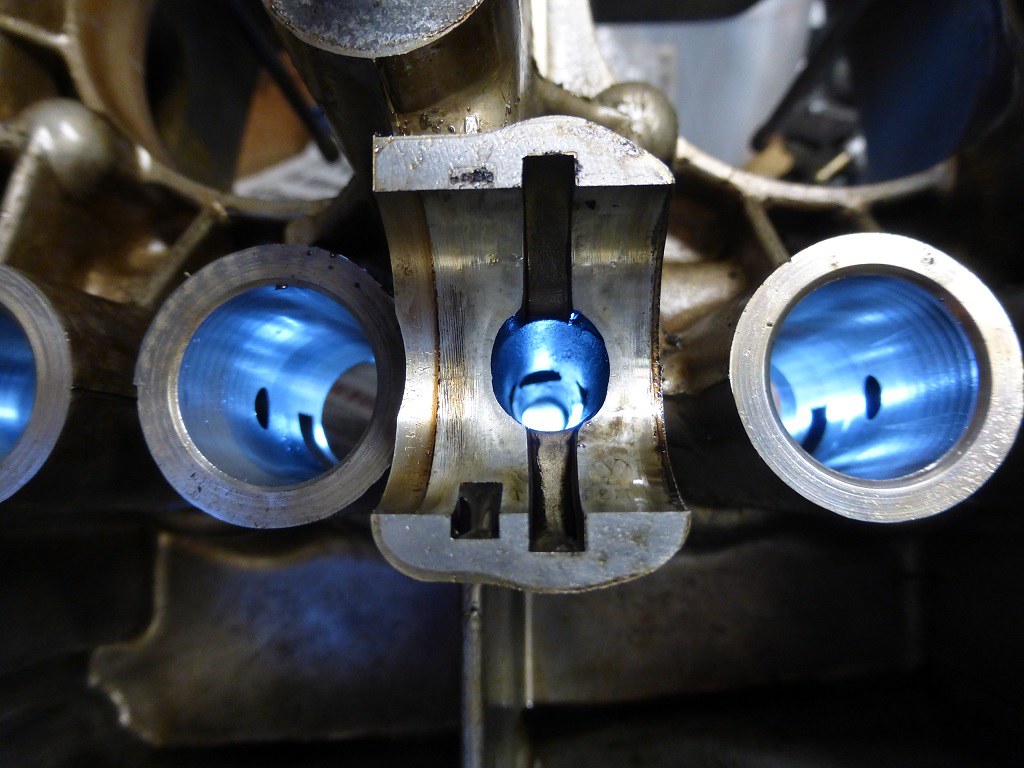

And another thing worth noting , there is a plugged drilling to the high pressure oil gallery between cylinder 3&4 into the water jacket if you have your engine apart check it, if it fails you get oil in the water as the third pic shows.

hard to see usually because the studs hide it but in this pic with a broken stud it becomes very clear, it a drilling to get to the tappet/low pressure oil switch seen on the second picture

P1030802

P1030802 by

Paul_Barr, on Flickr

P1030798

P1030798 by

Paul_Barr, on Flickr

failed plug to oil gallery

failed plug to oil gallery by

Paul_Barr, on Flickr

Re: WBXmayo

Posted: 11 Jan 2018, 18:39

by itchyfeet

Ohhh look what turned up today

P1090159

P1090159 by

Paul_Barr, on Flickr

I'm going to try and measure it and compare with the old cam so I made a jig up ( bolts are turned to a cone)

P1090163

P1090163 by

Paul_Barr, on Flickr

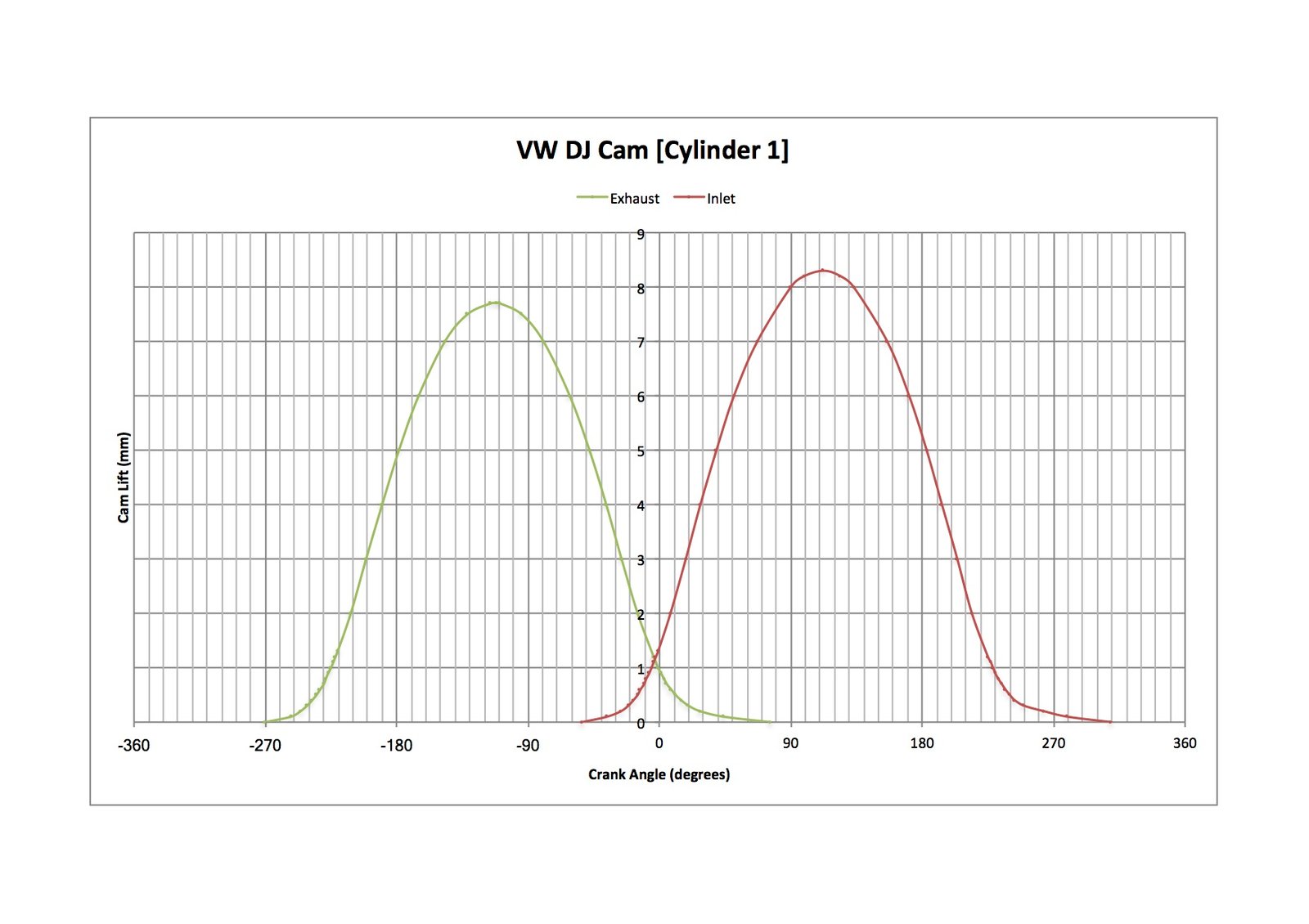

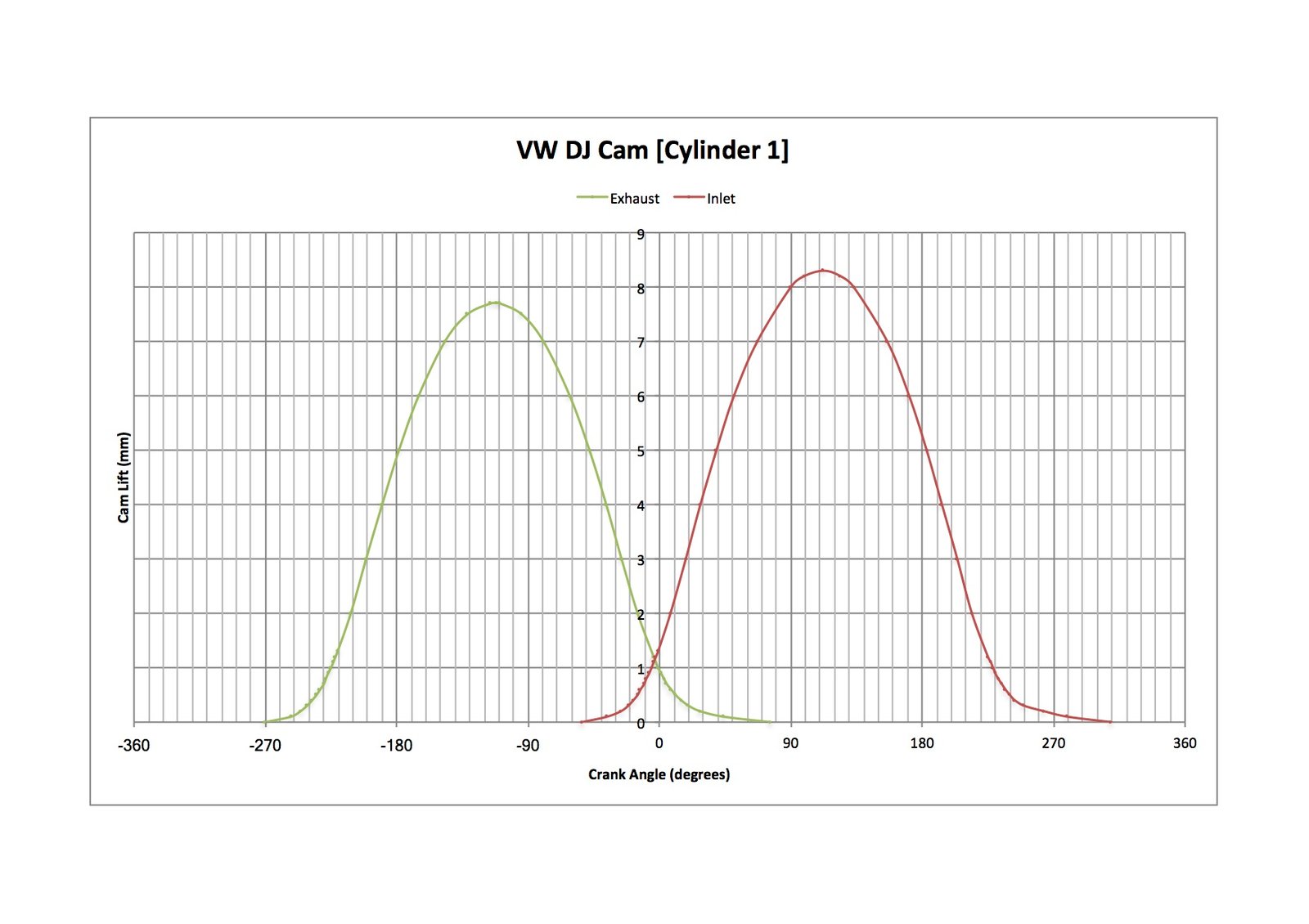

it's a lot harder than it looks, it's frying my brain, I'm trying to get numbers that look like this but they don't yet. Cam turns anticlockwise as crank turns clockwise and zero is I assume the mark on the cam gear

I must have the scale wrong

I'm also wondering if the old cam is even a DJ because it doesn't look the same as CJH's graph

P1080932 by Paul_Barr, on Flickr

P1080932 by Paul_Barr, on Flickr P1080931 by Paul_Barr, on Flickr

P1080931 by Paul_Barr, on Flickr P1050648 by Paul_Barr, on Flickr

P1050648 by Paul_Barr, on Flickr P1080930 by Paul_Barr, on Flickr

P1080930 by Paul_Barr, on Flickr 20170907_174246 by Paul_Barr, on Flickr

20170907_174246 by Paul_Barr, on Flickr P1080935 by Paul_Barr, on Flickr

P1080935 by Paul_Barr, on Flickr P1080938 by Paul_Barr, on Flickr

P1080938 by Paul_Barr, on Flickr 20171213_183201 by Paul_Barr, on Flickr

20171213_183201 by Paul_Barr, on Flickr P1080940 by Paul_Barr, on Flickr

P1080940 by Paul_Barr, on Flickr P1080939 by Paul_Barr, on Flickr

P1080939 by Paul_Barr, on Flickr P1080944 by Paul_Barr, on Flickr

P1080944 by Paul_Barr, on Flickr P1090018 by Paul_Barr, on Flickr

P1090018 by Paul_Barr, on Flickr P1090020 by Paul_Barr, on Flickr

P1090020 by Paul_Barr, on Flickr P1090021 by Paul_Barr, on Flickr

P1090021 by Paul_Barr, on Flickr P1090023 by Paul_Barr, on Flickr

P1090023 by Paul_Barr, on Flickr P1090024 by Paul_Barr, on Flickr

P1090024 by Paul_Barr, on Flickr P1090027 by Paul_Barr, on Flickr

P1090027 by Paul_Barr, on Flickr P1090041 by Paul_Barr, on Flickr

P1090041 by Paul_Barr, on Flickr P1090042 by Paul_Barr, on Flickr

P1090042 by Paul_Barr, on Flickr P1090044 by Paul_Barr, on Flickr

P1090044 by Paul_Barr, on Flickr P1090046 by Paul_Barr, on Flickr

P1090046 by Paul_Barr, on Flickr Type 4 little end spec by Paul_Barr, on Flickr

Type 4 little end spec by Paul_Barr, on Flickr P1030802 by Paul_Barr, on Flickr

P1030802 by Paul_Barr, on Flickr P1030798 by Paul_Barr, on Flickr

P1030798 by Paul_Barr, on Flickr failed plug to oil gallery by Paul_Barr, on Flickr

failed plug to oil gallery by Paul_Barr, on Flickr P1090159 by Paul_Barr, on Flickr

P1090159 by Paul_Barr, on Flickr P1090163 by Paul_Barr, on Flickr

P1090163 by Paul_Barr, on Flickr