I noticed it quite soon after install, but I had a sump plug leak so hoped it was that but after 500 miles it's still there.

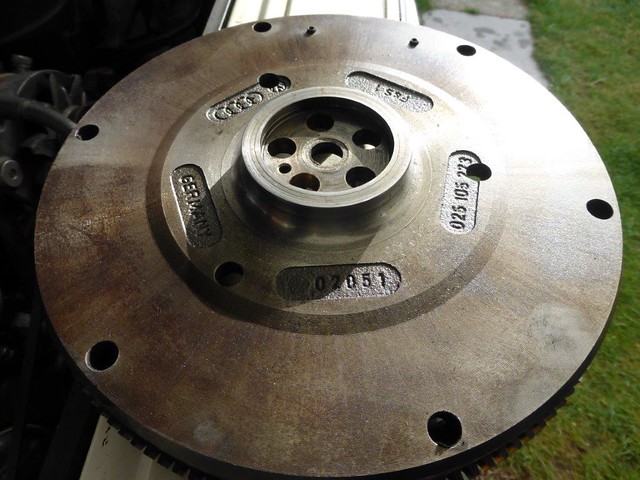

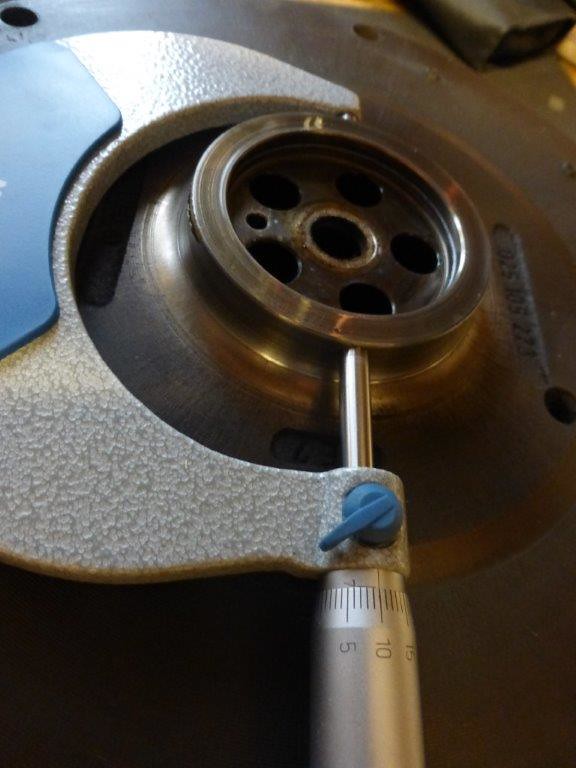

It had a new Elring oil seal and new o ring, flywheel looked good, end float was set, I hope it's not the case seal.

I could just get on with rebuilding the old engine but that could take me months and if I leave it I will contaminate the clutch and then I may break down.

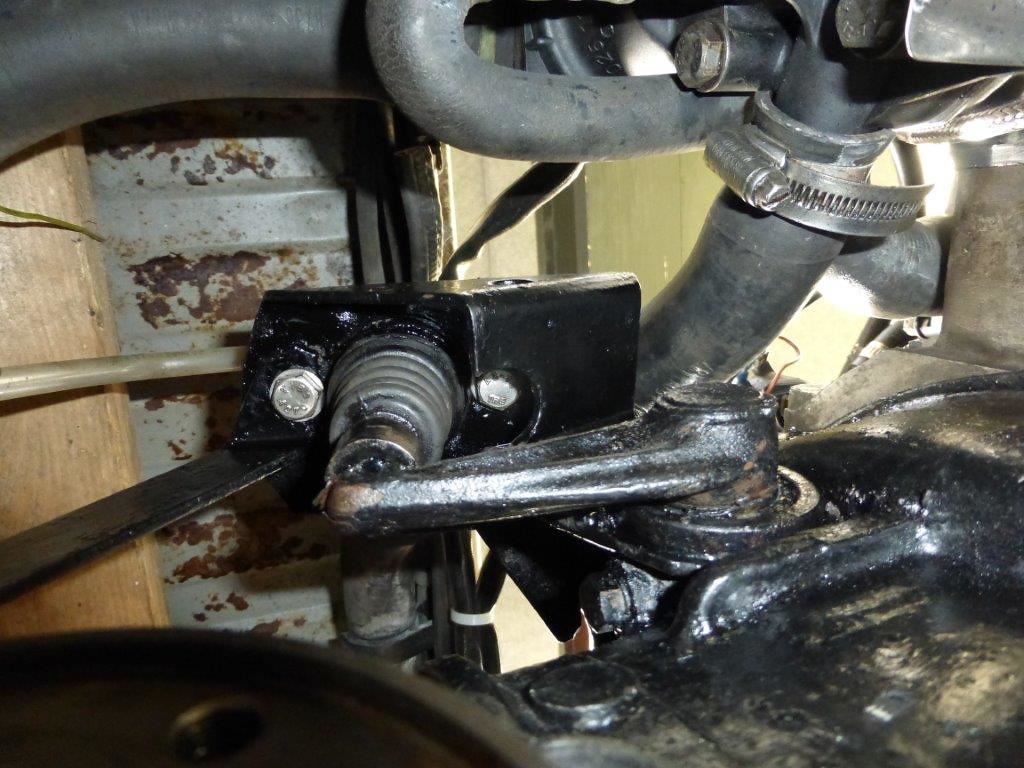

No choice but to remove the gearbox ( again) and investigate

No point fitting the stainless exhaust with an oil leak above it.

P1050078 by Paul_Barr, on Flickr

P1050078 by Paul_Barr, on Flickr P1050100 by Paul_Barr, on Flickr

P1050100 by Paul_Barr, on Flickr