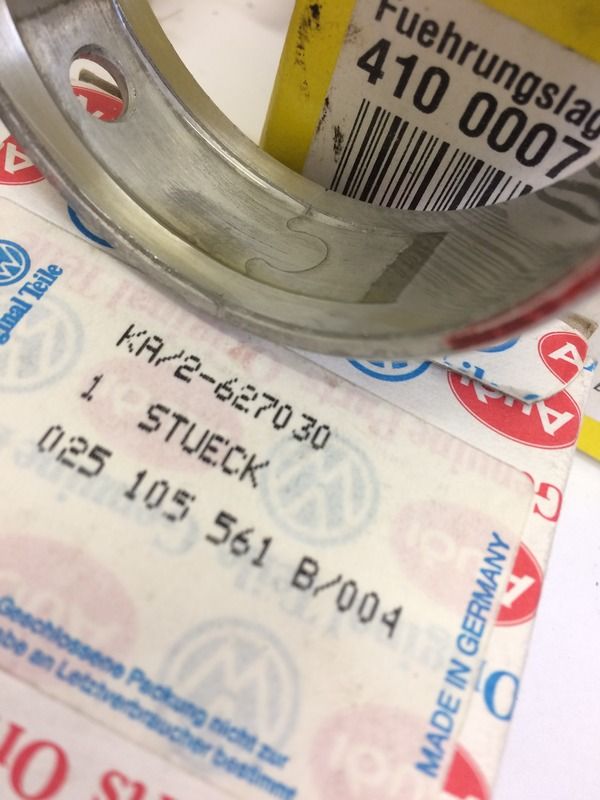

Part of the reason for the delay is a wait for new crank main bearings to arrive from VW Classic.

When I first started the rebuild I took the crank/case/liners to an engineering machine shop (recommended to me by a few people) to get them to check everything over. When I returned a week later I was greeted with the line "yeah mate, they're all in tolerance, should accept new standard bearings ok"......no dimensional report and a tenner handed over put initial doubts in mind about how much effort had gone into checking stuff.

So I naively rushed off to Brickwerks and bought a set of "std" mains bearings and started to build.

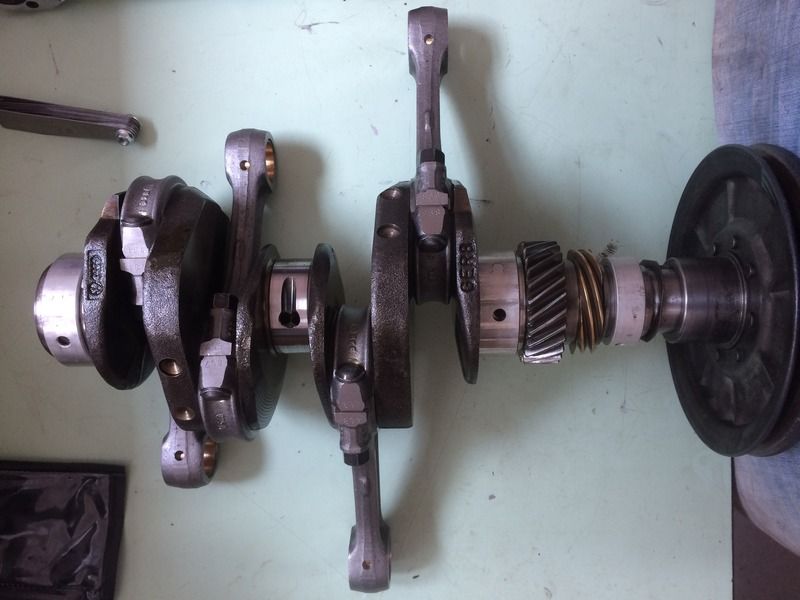

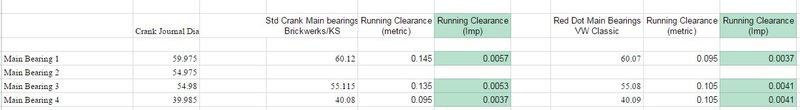

Those words played on my mind though so I decided to buy some mics and get measuring. After comparing my journal sizes to those shown in the Bentley manual it turned out they are in tolerance to a standard size......but there are 2 standard sizes, known as blue cranks and red cranks (marked up with paint dots originally).....and my journals were mic'ing up at the smaller red-dot size. No sign of the paint on my crank now though......

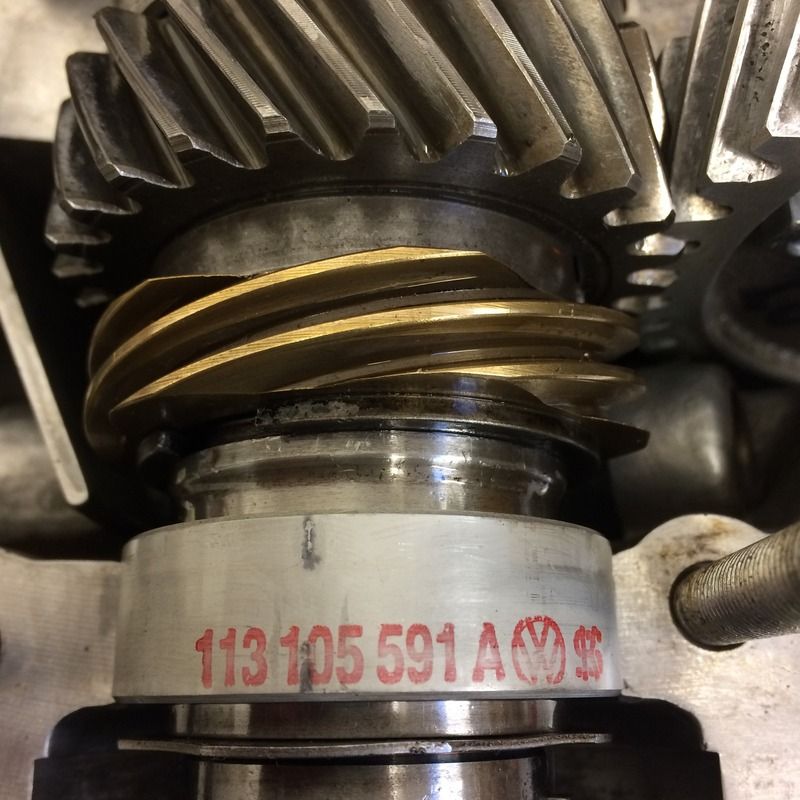

So feeling a bit silly that I hadn't checked stuff myself I ordered a set of red-dot bearings.....luckily still available from VW classic, albeit with a 3 week wait (and not cheap).

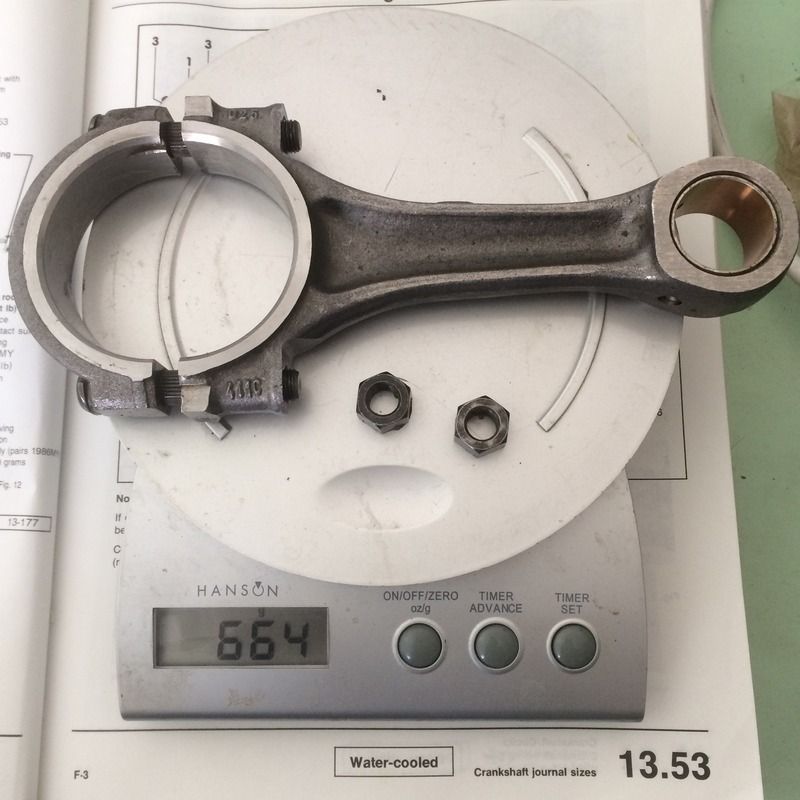

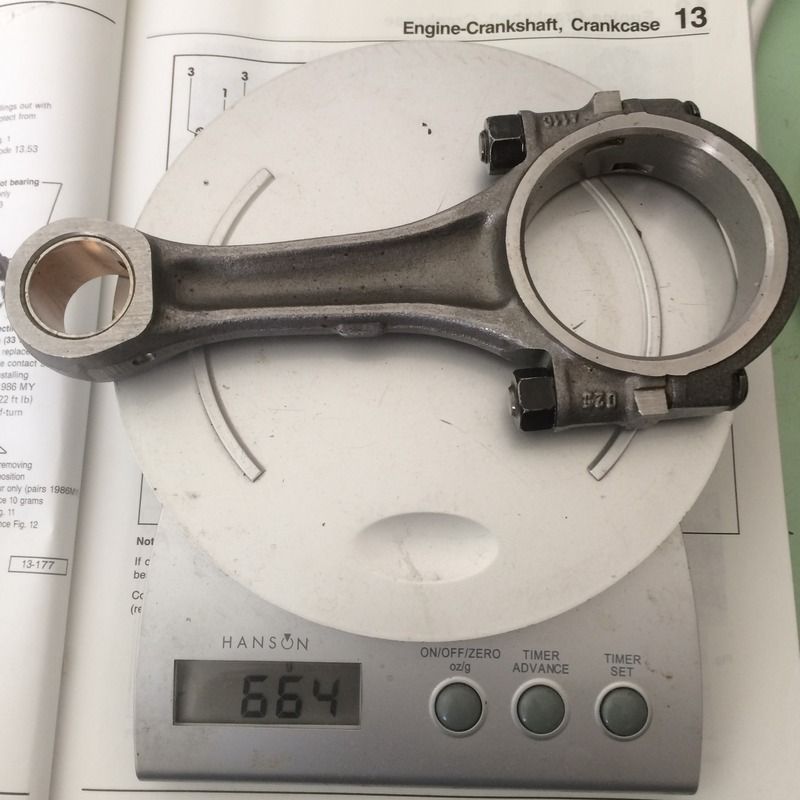

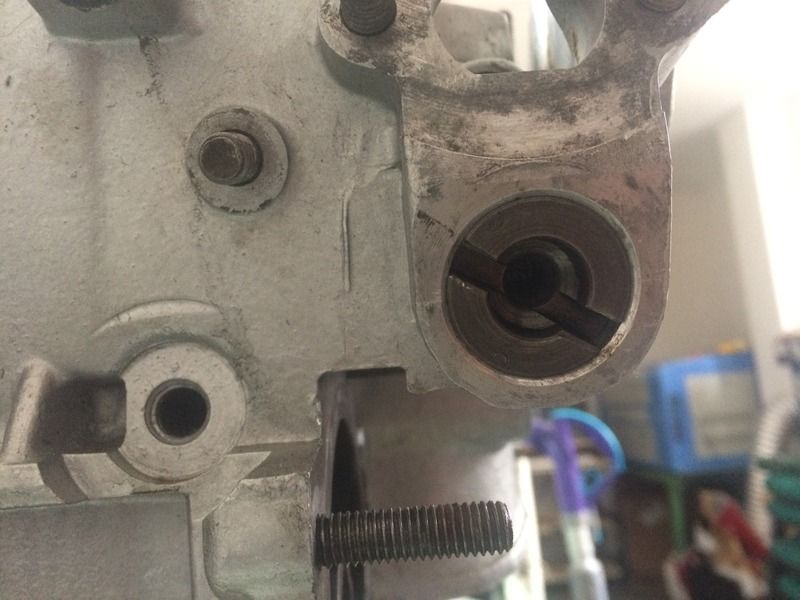

They arrived a couple of weeks ago so earlier this week I broke out the mics and telescopic bore gauges and measured stuff up to see what clearances I'd now be running. If I'd run with the "std" size bearings I'd be looking at over 5thou clearance....with the proper red-dot bearings I'm looking at around 4thou.....which is a relatively large clearance for crank mains(?) but what the wbx engine runs as standard (according to a few other sources on t'internet).

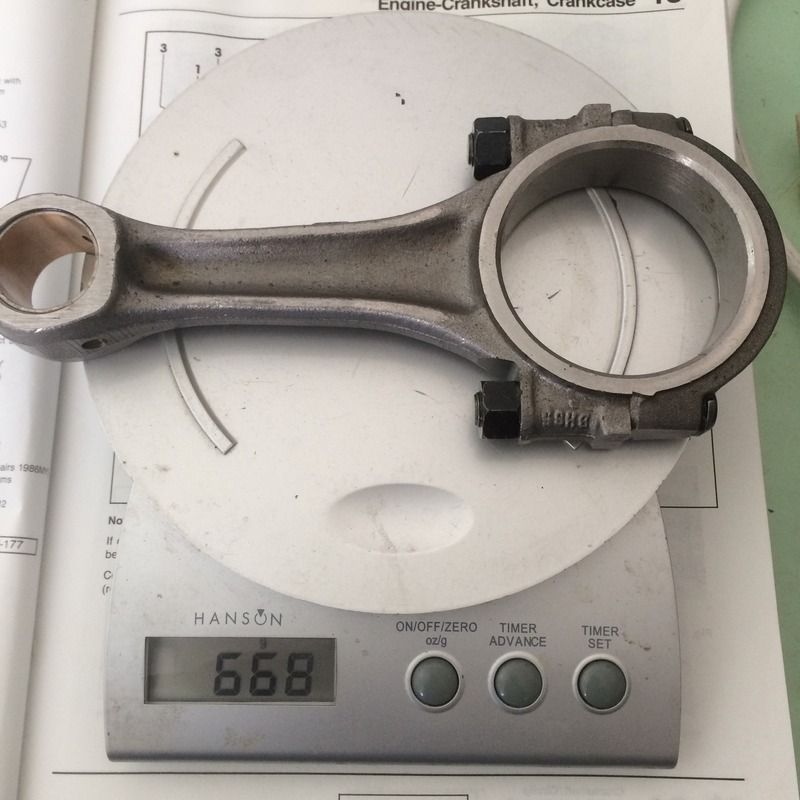

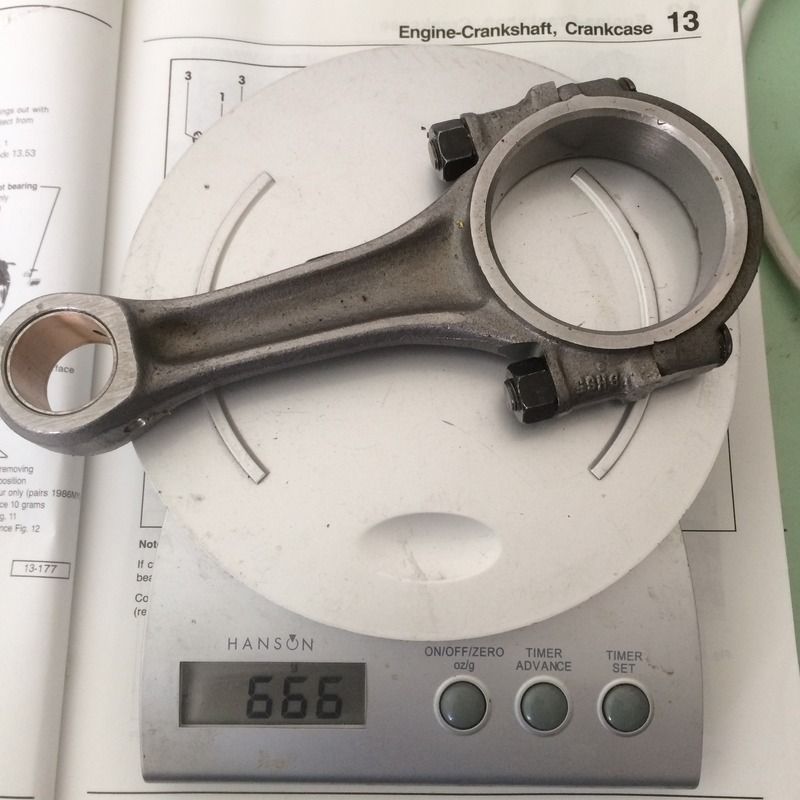

Anyways - here's what I measured (as accurate as I could measure using mics and telescopic bore gauges) - thought it might be good for reference.

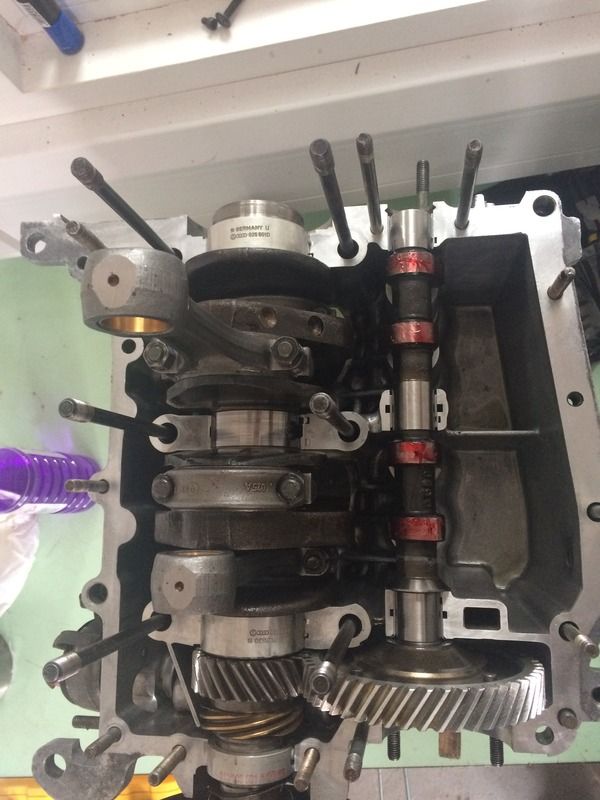

So after an hour or so of stripping the crank down again to remove the std bearings and replace with the new red-dot bearings I'm back to where I was 6 weeks ago!

Red-dot bearing notified by the /004 suffix (and the red paint)