Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Moderators: User administrators, Moderators

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I wonder what stock cam is like? I have a brand new DG cam somewhere.

Get your pump back yet?

Get your pump back yet?

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

itchyfeet wrote: Get your pump back yet?

Nope. Last week he simply said "some time next week", accompanied by sucking of teeth. That's one big reason that I'm glad I don't have to look at having my tappets reprofiled.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

itchyfeet wrote:I wonder what stock cam is like? I have a brand new DG cam somewhere.

Yes, it would be interesting to know if the lobes on the stock cam are tapered. Good luck measuring them though - I think a couple of thou will be difficult to measure reliably across the cam shape.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I skived off early to make a start on the next phase - removing the gearbox and driveshafts. I've been dreading this bit because manhandling the gearbox out seems hard, and because I've heard horror stories about getting the 24 driveshaft bolts out without rounding the socket heads. And frankly the bolts inside the trailing arms seem utterly inaccessible, and I had visions of having to rotate the wheels to access each bolt one by one, which would mean jacking the van up even further, taking it out of gear and releasing the handbrake - none of which I was happy about given that it's up on ramps at the moment and on sloping ground.

So here's how I'd left my van after removing the engine at the weekend.

So first off, starter out, slave cylinder off (and both of those jobs are a great deal easier when you can sit where there's normally an engine ), reversing switch wires disconnected, slave cylinder pipe separated from gearbox, gear selector linkage removed.

), reversing switch wires disconnected, slave cylinder pipe separated from gearbox, gear selector linkage removed.

Next, the gearbox driveshaft bolts. 12-point star socket heads - good, I've heard they're better than the hex socket heads. They all came out easily, and all are accessible without having to turn the wheels.

Now, how am I going to lower the gearbox in a controlled way? A trolley jack seemed an easy approach, but finding the balance point could be tricky, and getting it down and out without the gearbox toppling off the trolley jack seemed like it might not be easy. So I decided to use the boat winch again. I fixed my chain to the top bellhousing bolts using a couple of D shackles.

Then I placed my trolley jack under the nose of the gearbox, and pushed my pallet trolley under the gearbox as far as the trolley jack.

Then I undid the bolt through the gearbox mount and started to lower the gearbox a bit at a time on both the trolley jack and the winch. Wait - what did I forget?! Ah yes, the earth strap, and the stuck driveshaft. Winch it back up, release both of those, and down it came without drama.

Gearbox out - so far so good. And the good thing about this approach is that it's easily reversible to get the new gearbox in.

Now the driveshaft bolts at the wheel ends. Headtorch on to peer into the darkness - oh, hex head sockets. Started with the offside - all six moved easily enough, and the driveshaft came out. It turns out that with the gearbox end disconnected the drive shaft moves around enough that you can get to all six without having to turn the wheel - that's a relief. Nearside was a different story though - all six bolts were really tight. I tried my impact driver but it wouldn't shift them. So I felt my only choice was to get my 750mm breaker bar on them, but of course this increases the risk of rounding off the heads. So I hammered the drive bit well into the bolt to give it the best chance of not rounding off, then applied the breaker, and thankfully all six moved. What a relief.

I'm on a roll! I've booked the next two days off as leave. Should be able to make some good progress at tidying the engine bay a bit now that the major removal jobs are out of the way.

So here's how I'd left my van after removing the engine at the weekend.

So first off, starter out, slave cylinder off (and both of those jobs are a great deal easier when you can sit where there's normally an engine

Next, the gearbox driveshaft bolts. 12-point star socket heads - good, I've heard they're better than the hex socket heads. They all came out easily, and all are accessible without having to turn the wheels.

Now, how am I going to lower the gearbox in a controlled way? A trolley jack seemed an easy approach, but finding the balance point could be tricky, and getting it down and out without the gearbox toppling off the trolley jack seemed like it might not be easy. So I decided to use the boat winch again. I fixed my chain to the top bellhousing bolts using a couple of D shackles.

Then I placed my trolley jack under the nose of the gearbox, and pushed my pallet trolley under the gearbox as far as the trolley jack.

Then I undid the bolt through the gearbox mount and started to lower the gearbox a bit at a time on both the trolley jack and the winch. Wait - what did I forget?! Ah yes, the earth strap, and the stuck driveshaft. Winch it back up, release both of those, and down it came without drama.

Gearbox out - so far so good. And the good thing about this approach is that it's easily reversible to get the new gearbox in.

Now the driveshaft bolts at the wheel ends. Headtorch on to peer into the darkness - oh, hex head sockets. Started with the offside - all six moved easily enough, and the driveshaft came out. It turns out that with the gearbox end disconnected the drive shaft moves around enough that you can get to all six without having to turn the wheel - that's a relief. Nearside was a different story though - all six bolts were really tight. I tried my impact driver but it wouldn't shift them. So I felt my only choice was to get my 750mm breaker bar on them, but of course this increases the risk of rounding off the heads. So I hammered the drive bit well into the bolt to give it the best chance of not rounding off, then applied the breaker, and thankfully all six moved. What a relief.

I'm on a roll! I've booked the next two days off as leave. Should be able to make some good progress at tidying the engine bay a bit now that the major removal jobs are out of the way.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

as soon as those CVs are seperated from the boots thay can fall over and fall appart, do yourself a favour and tie wrap the boot to the joint to keep it upright.

When you take them appart remove circlip first then take cable ties off just before drifting it off and keep it square, don't let go for a second.

Trust me if it falls appart it's a very hard job to get it back together.

P1050618 by Paul_Barr, on Flickr

P1050618 by Paul_Barr, on Flickr

When you take them appart remove circlip first then take cable ties off just before drifting it off and keep it square, don't let go for a second.

Trust me if it falls appart it's a very hard job to get it back together.

P1050618 by Paul_Barr, on Flickr

P1050618 by Paul_Barr, on Flickr

Last edited by itchyfeet on 16 Aug 2017, 17:26, edited 1 time in total.

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

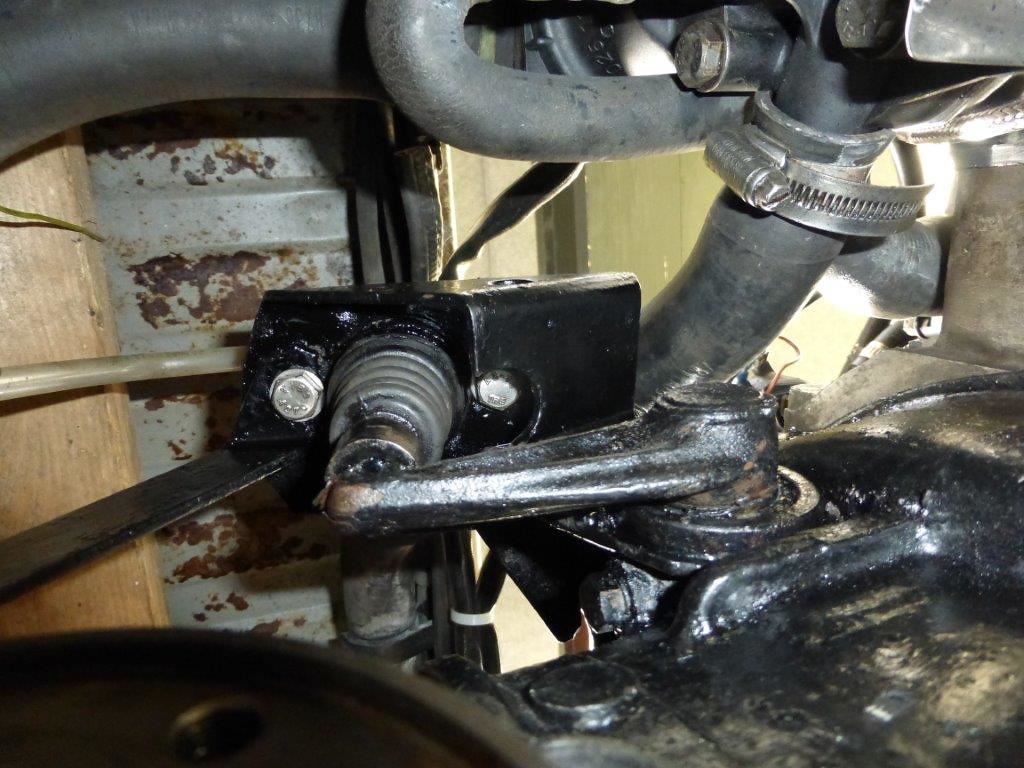

Worth doing the slave cylinder bracketmod while it's out , either weld a nut underneath or if you have no welding equipment you can cut a slot to get a socket on.

front bolt is easy to access

P1050126 by Paul_Barr, on Flickr

P1050126 by Paul_Barr, on Flickr

front bolt is easy to access

P1050126 by Paul_Barr, on Flickr

P1050126 by Paul_Barr, on Flickr

Last edited by itchyfeet on 16 Aug 2017, 17:24, edited 1 time in total.

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Haha, yes, I've seen the warnings about the CV joints before. On this occasion though I don't mind, as I've got four new CV joints to go on. In fact that's the reason I've removed the drive shafts in the first place. My old joints had been clicking, grumbling and grinding for a long time, so I bought replacements when they came up for a good price. Actually though, ever since I greased them in-situ they've been fine. But if I'm ever going to fit the replacements, now's the time.

That's a good idea with the slave cylinder bracket, thank you - I'll definitely look at doing something like that. What were they thinking when they designed that bracket. I don't weld, but I should be able to cut a hole or slot for a socket.

That's a good idea with the slave cylinder bracket, thank you - I'll definitely look at doing something like that. What were they thinking when they designed that bracket. I don't weld, but I should be able to cut a hole or slot for a socket.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Remind us why you removed gear box?

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I have one of Aidan's creations ready to go back in. So that'll be a whole new drive train.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

-

what2do

- Registered user

- Posts: 2824

- Joined: 05 Oct 2012, 08:55

- 80-90 Mem No: 11974

- Location: Salisbury

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Great idea to get some grease in there whilst in situ. Will definitely be copying this idea next time the van is on the ramps.

Surprised Itchy hasn't commented on the benefit of tying up the arm in the slave cylinder to prevent it dropping down and letting oil leak out.

Why would the glass be anything other than half full?

'89 panel van, 1.9 DG.

'89 panel van, 1.9 DG.

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

Surprised Itchy hasn't commented on the benefit of tying up the arm in the slave cylinder to prevent it dropping down and letting oil leak out.

Piston can fall out of slave for sure if the boot is tired I made a jig to hold it in

when box is back yes tie up clutch release lever to stop the same and nore importantly stop thrust bearing clips coming off the fork

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

itchyfeet wrote: when box is back yes tie up clutch release lever to stop the same and nore importantly stop thrust bearing clips coming off the fork

Not sure what you're suggesting here - I tried moving the clutch lever about on my old gearbox, and the release bearing just moves in and out on the guide tube - no danger of the clips coming off as far as I can see. Am I missing the point?

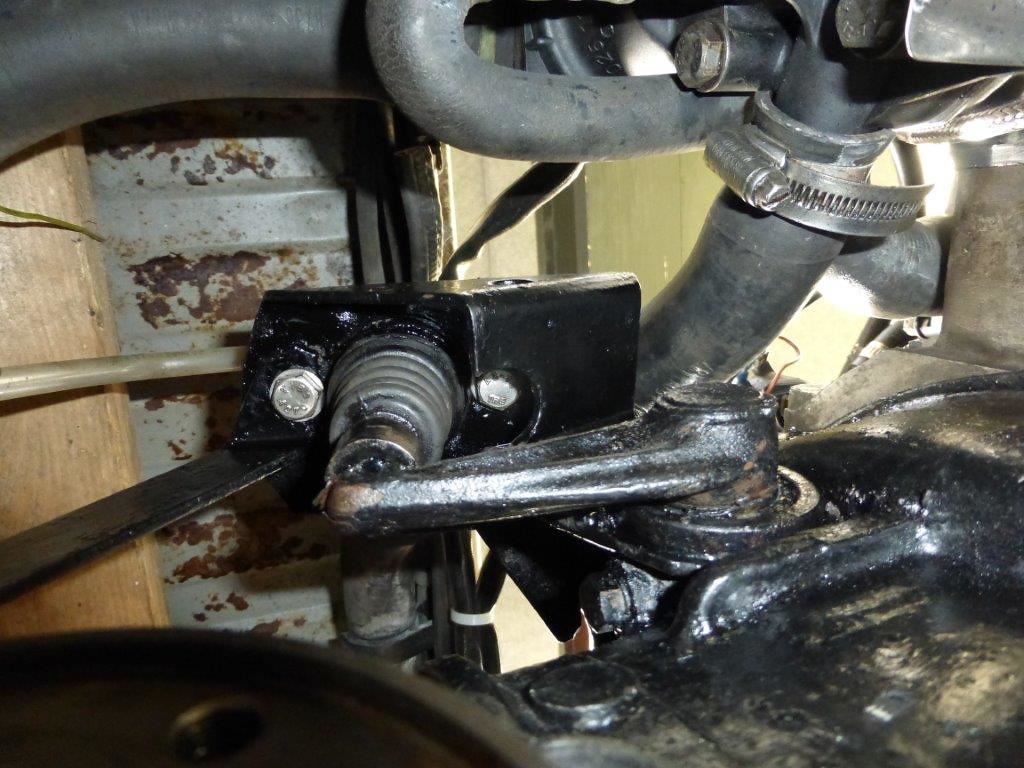

Made good progress today - paced myself in the sun. I separated the old CV joints from the driveshafts. The grease I'd pumped in a year ago seems to have been plenty, but the two wheel-side CV joints seem to be much older than the ones at the gearbox end and were pretty clogged with dried-up grease. I refurbed the spreader plates a bit - a scrub up in paraffin and some paint. Here's proof

Fitting the new CV joints has to be the messiest job there is - got through a whole roll of workshop paper towel. They went back together ok, and I fitted one bolt with a nut on the end to keep everything together, and I bagged them up to keep them clean and to stop everything else getting covered in black grease. They went back onto the axle shafts inside the trailing arms very easily - refurbed spreader plates, new Schnorr washers, and new 12-point star bolts.

I then refitted the gearbox, using the winch and trolley jack as per the removal, and it went in very smoothly. I'd looked at modding the slave cylinder bracket as per Itchyfeet's suggestion, but it's fairly thick steel plate, and I think the difficulty of cutting an access hole without the proper tools (and it seemed to be trapped on the gearbox) outweighed the difficulty of getting an open-ended spanner on the nut - I'd done it before so I figured I could do it again if necessary.

Fitting the first gearbox CV joint was easy - to align the holes I just had to turn the opposite drive flange. But when I came to fit the other one, the holes didn't line up, and obviously at that point I couldn't turn the opposite drive flange because it was connected to a wheel, so I had visions of having to lift a wheel after all. So thinking cap on - I slid the old clutch friction plate on the input shaft to give me some torque, selected a gear (any gear) at the selector input, and then by turning the clutch plate I was able to turn the drive flange until the bolt holes lined up.

Torqued everything up, and then lowered the gearbox onto my jack stand as before.

Home stretch now - just the engine and one of my radiators to go, plus the oil cooler.

"I'm a man of means, by no means....King of the Road!"

1983 Viking Xplorer, 2.1DJ

1983 Viking Xplorer, 2.1DJ

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

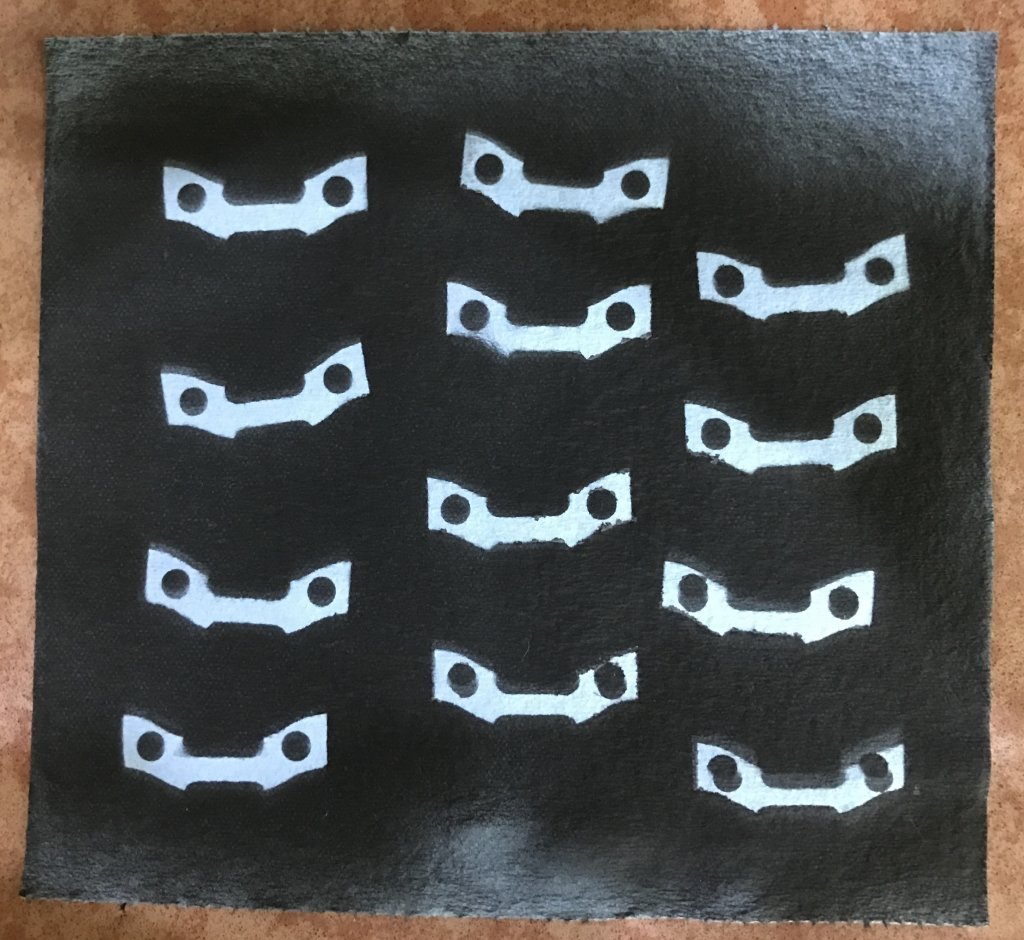

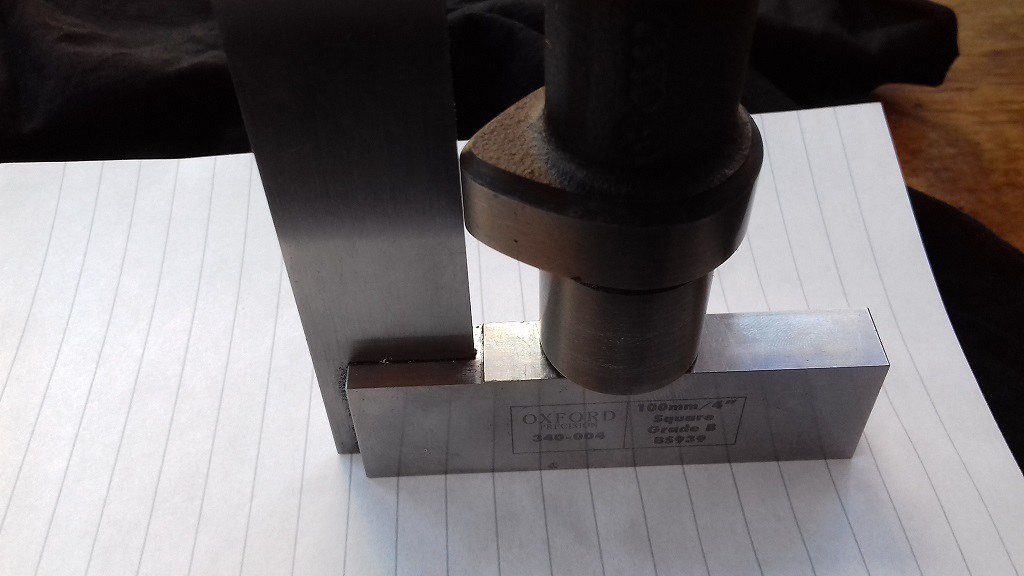

CJH wrote:itchyfeet wrote:I wonder what stock cam is like? I have a brand new DG cam somewhere.

Yes, it would be interesting to know if the lobes on the stock cam are tapered. Good luck measuring them though - I think a couple of thou will be difficult to measure reliably across the cam shape.

looks flat to me

20170810_180652 by Paul_Barr, on Flickr

20170810_180652 by Paul_Barr, on Flickr- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

CJH wrote:itchyfeet wrote: when box is back yes tie up clutch release lever to stop the same and nore importantly stop thrust bearing clips coming off the fork

Not sure what you're suggesting here - I tried moving the clutch lever about on my old gearbox, and the release bearing just moves in and out on the guide tube - no danger of the clips coming off as far as I can see. Am I missing the point?

Maybe your clutch lever is a bit stiff from corrosion but mine isn't and as the lever falls by it's own weight and the the slave cylinder it slowly slides the release bearing forward (because clutch is missing), the clips eventually come off the end of the fork.

If you just push it back you end up with the clips ( or just one clip) the wrong side of the fork and it looks fine but it's not.

TWICE I have made this stupid mistake, the first time tools were away and I had washed up before I tried the clutch.

Last edited by itchyfeet on 10 Aug 2017, 18:15, edited 1 time in total.

- itchyfeet

- Registered user

- Posts: 12427

- Joined: 23 Jul 2007, 17:24

- 80-90 Mem No: 12733

- Location: South Hampshire

Re: Early 1.9 to 2.1 conversion - stop me if I'm being stupid!

I'd looked at modding the slave cylinder bracket as per Itchyfeet's suggestion, but it's fairly thick steel plate, and I think the difficulty of cutting an access hole without the proper tools (and it seemed to be trapped on the gearbox) outweighed the difficulty of getting an open-ended spanner on the nut - I'd done it before so I figured I could do it again if necessary.

You do need a hole saw it's true

P1050102 by Paul_Barr, on Flickr

P1050102 by Paul_Barr, on FlickrThe problem is not just access it's getting a nut onto the bolt to start with just two hands, I have used a bit of beer can before to hold the bolt in place.