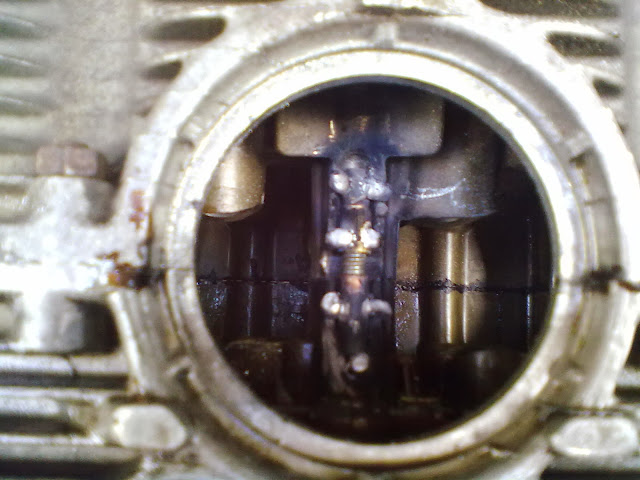

A bit of Full frontal engine Porn for you.....

This is the soft under belly of a 1981'ish, (reconned by VW long ago)...CU 2 litre Aircooled

The more observant among you will spot the central oil strainer bolt is well off centre..

Caused I think by over enthusiastic tightening of the 'blind' nut.. presumably to stop an oil leak..breaking the stud off inside the case.. engine apart..

20 centimes of washer might have saved the day...

Never mind... it's all a learning curve....

So, I now strip down the block and look to see whether I can get away with welding surgery ......or.....

Any one got a GOOD CU case out there,

I'll keep you posted..

Cordialement